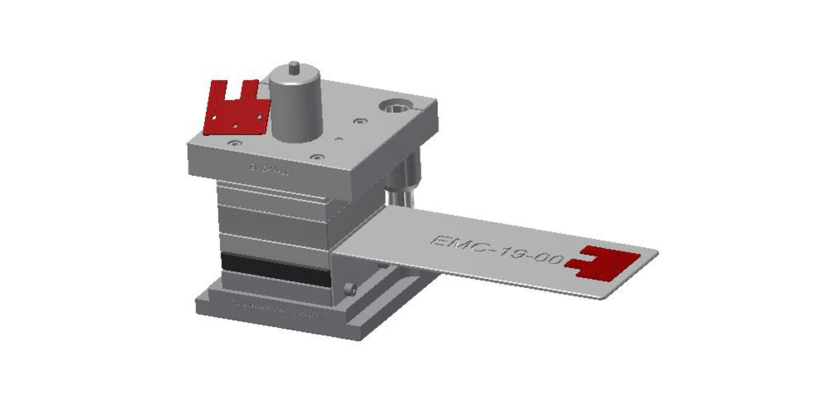

Streamline your press tool design process with our comprehensive Compound Die 4 Inventor documentation. This specialized die set is designed to perform multiple operations—specifically blanking and piercing—simultaneously in a single press stroke. By executing these tasks at a single station, the compound die ensures absolute concentricity between the outer profile and the internal holes, a feat often difficult to maintain in progressive stages. These drawings are optimized for the Inventor environment, utilizing the software’s advanced assembly constraints and iProperty data for seamless manufacturing integration.

The provided desenho package includes fully detailed assembly models and part files, allowing you to examine the intricate relationship between the blanking punch and the piercing die. By analyzing the specialized stripper mechanism and the internal knockout system documented in these blueprints, engineers can prevent part deformation and ensure consistent ejection cycles. We offer these high-fidelity Inventor resources for free to help tool designers reduce development cycles and increase stamping accuracy in high-volume production runs.

Our files leverage Inventor’s parametric modeling, making it easy to adjust clearances and material thicknesses to suit your specific project needs. Whether you are producing precision washers or electrical laminations, this design provides a robust blueprint for high-performance tooling. Download this essential CAD asset today to take full advantage of professional-grade tool design within your digital prototyping workflow.

Principais recursos:

- Single-Stroke Concentricity: Unique architecture that guarantees perfect alignment between the blanked perimeter and pierced holes.

- Autodesk Inventor Optimized: Native file compatibility with full access to assembly constraints and bill of materials (BOM).

- Internal Knockout System: Detailed spring-loaded or mechanical knockout designs to facilitate efficient part removal from the upper die.

- Precision Guide Pillar Layout: Features high-tolerance pillar and bushing specifications to maintain rigid alignment under tonnage.

- Tamanho compacto: Engineered to maximize efficiency within the press bed area, making it ideal for smaller capacity machines.