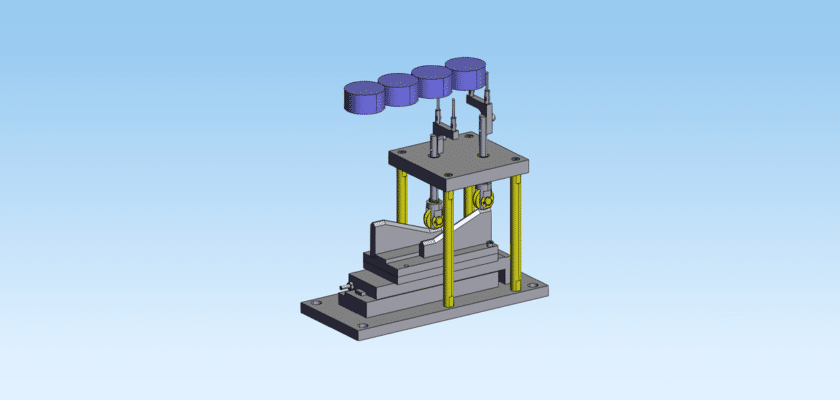

Master the art of high-speed repeatable motion with our professional Cutting Mechanism Using Plate Cam drawing. In the world of automated machinery, cam-driven systems are prized for their ability to provide perfect synchronization and specific motion profiles that are hard-coded into the hardware. This technical blueprint provides a complete design for a cam-actuated shear or blade assembly, ideal for applications like wire cutting, film slicing, or food portioning where high-cycle speeds and mechanical reliability are paramount.

The design focuses on the precision-engineered profile of the plate cam, which dictates the acceleration, dwell, and return of the cutting blade. By downloading this drawing from MechStream, you receive a detailed layout of the cam lobe geometry, the roller follower assembly, and the heavy-duty spring-return system that ensures the blade resets instantly after every stroke. Because the timing is mechanical, this system remains perfectly in sync with the rest of your machine’s drivetrain, eliminating the risk of electronic lag or sensor failure.

Using this professional resource allows your engineering team to implement a “maintenance-friendly” cutting solution. The documentation highlights the essential heat-treatment zones for the cam surface and provides specifications for high-load bearings that support the main drive shaft. Whether you are building a textile loom, a high-speed packaging machine, or a dedicated cable processing unit, this drawing provides the structural integrity and motion precision required for industrial-standard performance.

Principais recursos:

- Customizable Motion Profile: Detailed cam geometry designed for rapid cutting strokes with controlled dwell times to prevent material snagging.

- Positive Follower Engagement: Features a reinforced roller follower design that minimizes friction and prevents wear on the cam profile.

- Mechanical Sync Logic: Direct-drive architecture that ensures the cutting action is physically locked to the machine’s primary rotation.

- Heavy-Duty Blade Guides: Includes precision linear ways that keep the cutting edge perfectly aligned, reducing burrs and extending blade life.

- Design com eficiência energética: Utilizes the kinetic energy of the rotating cam to deliver high-force impacts with minimal power consumption compared to pneumatic alternatives.