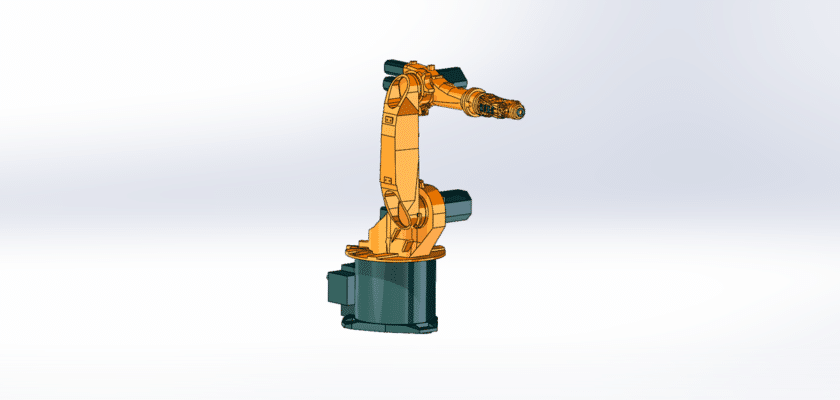

An D25 KR6 Robot Arm Drawing is a detailed technical illustration that outlines the design, components, and functionality of the D25 KR6 robotic arm. This drawing is essential for engineers, technicians, and operators involved in the deployment, programming, and maintenance of this specific robotic model.

Principais recursos:

- Overall Layout: A comprehensive view of the D25 KR6 robot arm, showcasing its structure and design, including joint configurations and reach capabilities.

- Joint Configuration: Detailed illustrations of the arm’s joints, typically including:

- Revolute Joints: Descriptions of the types of joints that provide rotational movement, allowing for flexible positioning.

- Degrees of Freedom: Information about the number of degrees of freedom (DOF) the arm provides, essential for understanding its operational range.

- Arm Segments: Diagrams showing the individual segments of the arm, including:

- Link Lengths: Specifications on the lengths of the arm segments, which determine the reach and workspace of the robot.

- Material Composition: Information about the materials used in construction, ensuring strength and durability.

- Actuation System: Descriptions of the motors and actuators used to drive the robot’s movements, including:

- Servo Motors: Details on the types of servo motors employed for precise control of each joint.

- Power Requirements: Specifications regarding the electrical requirements for operating the robot.

- End Effector: Information about the tool or gripper attached to the end of the arm, designed for specific tasks such as picking, placing, or assembly operations.

- Control System: Details about the control unit that manages the robot’s operations, including:

- Programming Interface: Information about the software used for programming the robot’s movements and tasks.

- Communication Protocols: Descriptions of the communication methods used to interface with the robot, such as Ethernet or serial connections.

- Safety Features: Information on integrated safety mechanisms, including emergency stop buttons, overload protection, and sensors that prevent accidents during operation.

- User Interface: Illustrations of any control panels or touchscreens that provide operators with access to robot settings, operational modes, and diagnostics.

- Maintenance Access Points: Guidance on areas designed for easy access during maintenance and repair, facilitating efficient servicing of the robot.

- Performance Specifications: Summary of key performance metrics, such as payload capacity, reach, speed, and precision, providing essential information for operational planning.

This drawing serves as a crucial reference for anyone involved in the operation and maintenance of the D25 KR6 robot arm, ensuring effective performance, reliability, and adherence to industry standards in various applications, including manufacturing, assembly, and material handling.