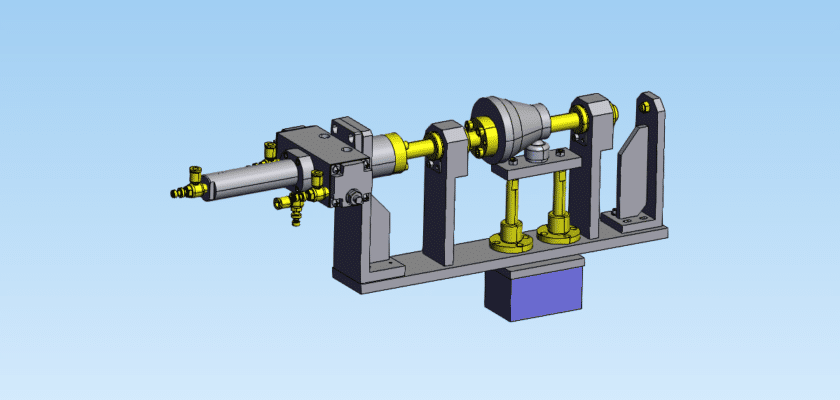

Unlock a new dimension of mechanical flexibility with our professional Multi-Stroke Mechanism Using Eccentric Conical Cams drawing. While standard flat cams are limited to a single fixed profile, a conical cam allows for variable stroke lengths by shifting the follower’s contact point along the axis of a tapered, eccentric cone. This technical CAD resource provides a comprehensive blueprint for this sophisticated transmission system, which is capable of adjusting output displacement in real-time without stopping the drive motor.

The design featured in this package focuses on the Axial Shifting Follower architecture. The drawing includes detailed layouts for the tapered cam profile, the splined drive shaft, and the linear actuator used to move the follower along the cone’s length. As the follower moves from the narrow end of the cone to the wide end, the eccentricity ($e$) increases, resulting in a larger mechanical stroke. By utilizing this blueprint from MechStream, you can design high-precision dosing pumps, variable-speed feeders, and textile machinery that require instantaneous adjustment of reciprocating travel.

Our technical documentation prioritizes contact mechanics and geometric accuracy. Because a conical cam involves complex surface contact, our drawing specifies the exact parabolic or cycloidal curves required to ensure smooth acceleration and minimize “point-loading” wear. Whether you are building an experimental variable-valve timing system or a custom packaging machine, this drawing provides the exact surface finish requirements ($Ra$), material hardening specs, and follower-alignment tolerances needed for a professional-grade, high-performance mechanism.

Principais recursos:

- Infinitely Variable Stroke Length: Allows for precise adjustment of linear output by simply sliding the follower along the conical axis.

- Synchronized Displacement Control: Detailed designs for the shifting fork or lead screw that manages the follower’s position on the cam.

- High-Strength Tapered Geometry: Engineered to handle high radial loads while maintaining a compact axial footprint.

- Optimized Pressure Angles: The cam profile is designed to maintain efficient force transmission regardless of the follower’s position on the cone.

- Specialized Follower Design: Includes specifications for spherical or tapered rollers that compensate for the changing surface diameter of the cam.