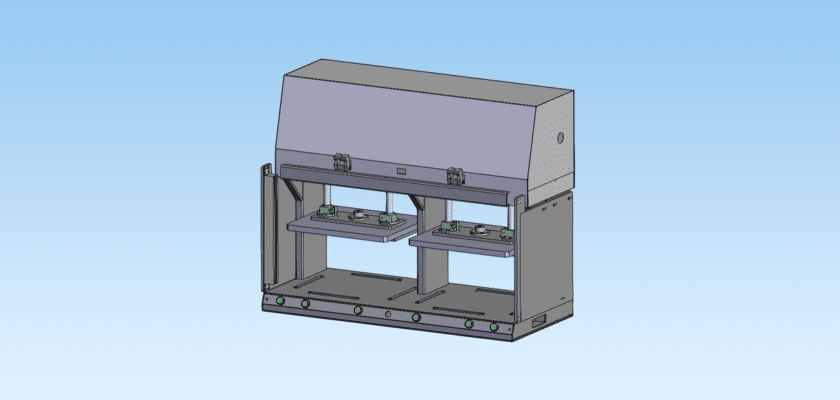

Maximize your production versatility by choosing to download our comprehensive Dual-Needle Bed Machine drawing. In the complex world of industrial knitting and technical textile production, the dual-needle bed configuration is the gold standard for creating seamless garments, 3D spacers, and heavy-duty ribbed fabrics. This technical drawing provides a detailed mechanical map of the synchronized needle bed architecture, offering vital insights into the needle selection mechanisms and the precise timing required between the front and rear beds. It is an essential asset for mechanical designers looking to develop or maintain high-speed textile equipment.

By downloading this CAD resource, you can analyze the structural framework that supports the immense tension of industrial knitting while maintaining micron-level alignment between the opposing needle banks. The drawing covers the critical cam tracks, needle sliders, and yarn carrier paths that define the machine’s efficiency and output quality. Whether you are engineering a new machine for medical textiles or optimizing an existing setup for sportswear manufacturing, these blueprints provide the exact dimensions and assembly logic needed to ensure smooth, high-speed operation without needle collision or yarn breakage.

Principais recursos:

- Synchronized Bed Alignment: Detailed schematics of the interlocking mechanisms that ensure the front and rear needle beds stay perfectly phased during high-speed strokes.

- Precision Cam Track Geometry: Insights into the heat-treated cam profiles designed to minimize friction and wear on the needle butts during rapid movements.

- Variable Gauge Scalability: A modular design approach that allows the needle bed to be configured for different needle densities and yarn weights.

- High-Tension Frame Stability: Architectural details for a cast-iron machine base that absorbs vibrations and prevents frame deflection under heavy fabric take-up loads.

- Integrated Yarn Feeding Path: Specifications for the tension-controlled yarn guides and carrier rails that ensure consistent stitch formation across the entire width of the bed.