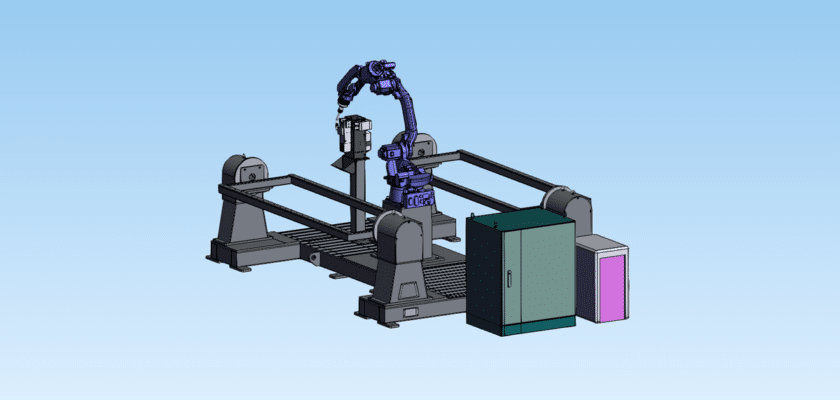

Supercharge your production cycle and maximize throughput with our exclusive, free drawing package para o Dual-Station Welding Positioner! This sophisticated equipment is essential for high-volume manufacturing environments where minimizing non-productive time is critical. By featuring two independent or synchronized work tables, the dual-station positioner allows the operator or robot to weld on one side while the other side is being loaded or unloaded. This virtually eliminates idle time, leading to a massive increase in overall welding efficiency and output.

Esse indispensable technical drawing set provides detailed blueprints for the entire dual-station setup. The plans cover the common central drive mechanism, the robust frame structure required for stability, the safety interlocks between the stations, and the design of the independent rotary and/or tilting tables. Manufacturing engineers, production managers, and systems integrators will find these accurate, industry-standard drawings essential for designing highly efficient automated or semi-automated welding cells. Stop wasting valuable production minutes on setup. By downloading this critical design asset today, you gain the technical specifications needed to build a continuous-operation welding system. Secure your free dual-station drawing now and redefine your production limits!

Principais recursos:

- Simultaneous Operation Design: Detailed schematics illustrating the layout that allows for independent or sequenced operation of the two distinct work stations.

- Indexing or Rotational Base: Blueprints showing the central mechanism (often a turntable or rotating shuttle) that moves the workpieces between the load/unload area and the welding zone.

- Safety Interlocks and Zoning: Layouts detailing the placement of safety fencing, light curtains, and control interlocks to ensure welder safety while working on one station.

- Individual Table Control: Schematics defining the motor, gearbox, and control systems for each station’s rotational and/or tilting movement, allowing for varied weld schedules.

- Optimized Footprint: Drawings highlighting the compact and efficient use of space designed to house two full-function positioners within a minimized area.