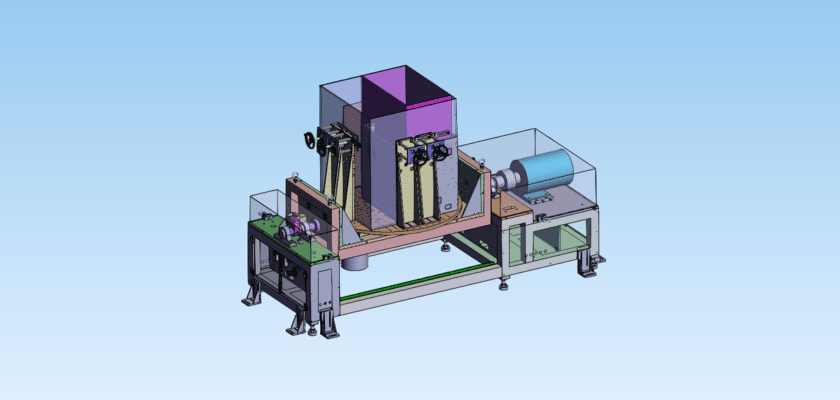

O Exploration Machinery Frame Robot Welding Workstation is a high-performance automated solution designed for the heavy-duty fabrication of structural frames used in mining and geological exploration. This comprehensive desenho provides the complete mechanical layout for a robotic cell capable of handling large-scale, high-strength steel assemblies. Unlike standard welding setups, this workstation is specifically engineered for the thick-walled sections and complex geometries typical of exploration equipment, ensuring deep penetration welds and structural consistency that manual welding simply cannot match.

By downloading this professional desenho, you gain access to a multi-axis system integration plan. This includes the heavy-duty robot mounting pedestal, the precision rotational positioner that allows for “downhand” welding positions, and the protective safety fencing system. The design incorporates advanced cable management for the welding torch and gas lines, ensuring a high degree of motion freedom without the risk of snagging. For engineers looking to modernize their production line, this CAD model offers a verified structural framework that balances robotic reach with workpiece accessibility, significantly reducing the R&D time required for custom automation.

This blueprint is optimized for industrial scalability. It details the mounting points for the power source, the wire feeder assembly, and the automated torch cleaning station. Utilizing this desenho ensures that your workstation layout adheres to modern safety standards, including localized fume extraction and light-curtain integration. It is an essential resource for manufacturing facilities aiming to increase throughput while maintaining the rigorous quality standards required for exploration machinery operating in extreme environments.

Principais recursos:

- Heavy-Duty Robot Pedestal: A vibration-dampening base designed into the desenho to support high-payload industrial robots during rapid motion cycles.

- Dual-Axis Workpiece Positioner: Detailed mechanics for a synchronized rotary table that keeps the weld seam in the optimal gravity position.

- Automated Torch Maintenance Hub: Integrated layout for tip cleaners and wire cutters to ensure continuous, high-quality welding operations.

- Modular Safety Enclosure: A robust fencing and shielding design that protects human operators from UV radiation and welding spatter.

- Smart Cable Management System: Dedicated routing paths for high-voltage and gas lines to prevent mechanical wear and operational downtime.