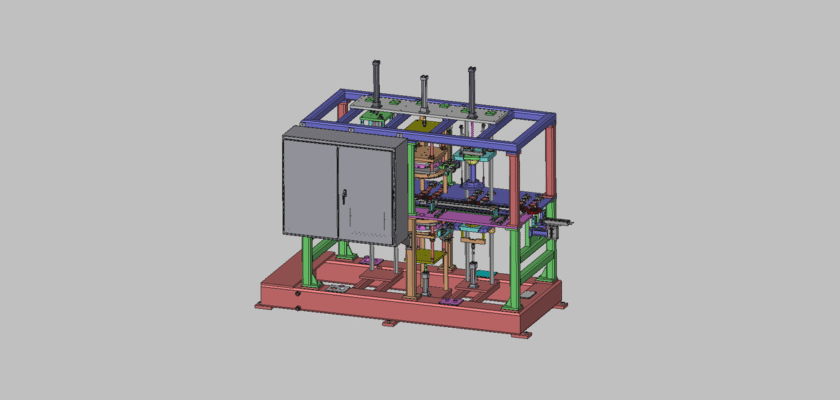

Boost your production efficiency with our comprehensive drawing for an Automated Fast Assembly Machine for Bushing Parts. This free CAD file provides a complete design blueprint for a high-speed, reliable system engineered to streamline the assembly of bushings into various components. This resource is indispensable for manufacturing engineers, machine designers, and automation specialists aiming to reduce manual labor, minimize errors, and significantly increase throughput on the factory floor.

Downloading this detailed technical drawing gives you a powerful head start in developing your own custom assembly solutions. The design showcases a fully integrated system, from part feeding and orientation to precise pressing and final ejection. It serves as both a practical guide for construction and a valuable educational tool for understanding the principles of modern automated assembly. By leveraging this professional design, you can shorten development cycles, de-risk your project, and implement a proven solution for one of manufacturing’s most common tasks.

Principais recursos:

- Alimentação automatizada de peças: Includes the design for a vibratory bowl feeder system that automatically sorts and orients bushing parts for consistent presentation to the assembly station.

- Precision Pneumatic Press: Details a robust pneumatic cylinder mechanism engineered for applying controlled and repeatable force to press-fit bushings accurately.

- Rotary Indexing Table: Features a multi-station rotary indexing table that efficiently transfers components between loading, assembly, and unloading stages, maximizing machine cycle speed.

- Sensor Integration Points: Clearly marks positions for sensors (e.g., proximity, vision) to ensure correct part presence, orientation, and successful assembly, enabling closed-loop control.

- Robust Structural Frame: The drawing specifies a sturdy, welded steel frame designed to provide maximum stability and minimize vibration during high-speed operation.