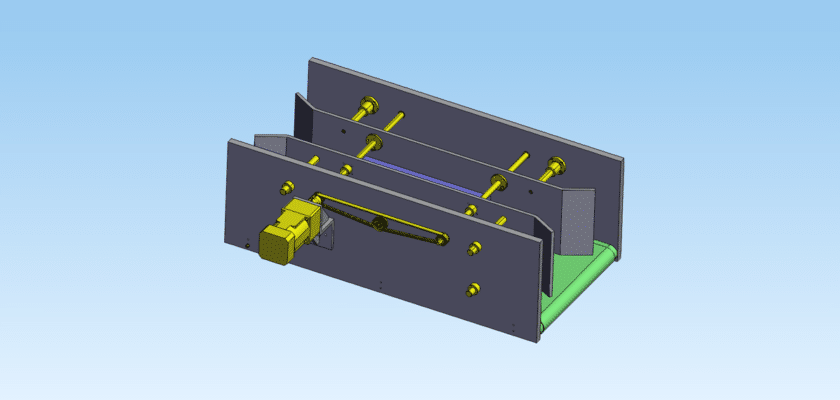

Master the mechanics of perfectly centered alignment with our professional Guide Block Spacing Adjustment Mechanism Based On Left- And Right-Hand Threaded Design drawing. In automated production and material handling, the ability to adjust the width of guide rails or centering blocks symmetrically relative to a fixed centerline is a common yet critical requirement. This technical blueprint utilizes the elegant logic of a dual-threaded lead screw, where one half features a right-hand thread and the other a left-hand thread. Turning a single handwheel or motor results in both guide blocks moving toward or away from each other at the exact same rate.

The design focuses on eliminating “racking” and ensuring high repeatability. By downloading this drawing from MechStream, you receive a detailed assembly including the specialized lead screw, the opposing-thread nut housings, and the precision linear shafts that keep the guide blocks perfectly parallel. This mechanism is an essential resource for engineers designing packaging equipment, labeling machines, or conveyor in-feed systems where product sizes change frequently, but the centerline must remain constant for downstream processing.

Implementing this professional-grade threaded solution allows your team to skip the complex synchronization of separate actuators. The documentation includes critical tolerances for the threaded interface to minimize backlash and provides material recommendations for the nuts—such as bronze or high-performance polymers—to ensure a long service life under constant adjustment cycles. Whether you are building a manual width-adjuster for a small lab or a motorized centering unit for a high-speed factory line, this drawing provides the mechanical precision and structural integrity required for industrial standards.

Principais recursos:

- Inherent Symmetrical Motion: The dual-thread architecture guarantees that the two guide blocks stay perfectly centered relative to the midpoint of the screw.

- Single-Point Operation: Allows for the adjustment of complex spacing requirements using only one input source, reducing mechanical complexity.

- Backlash Compensation Design: Includes details for tensioned nut assemblies or high-tolerance threads to ensure the blocks hold their position accurately.

- Heavy-Duty Linear Support: Features a dual-rod support system that absorbs lateral forces, preventing the lead screw from bending under load.

- Modular Block Mounting: Detailed specifications for the block interfaces, allowing for the attachment of various guide rail shapes or sensor brackets.