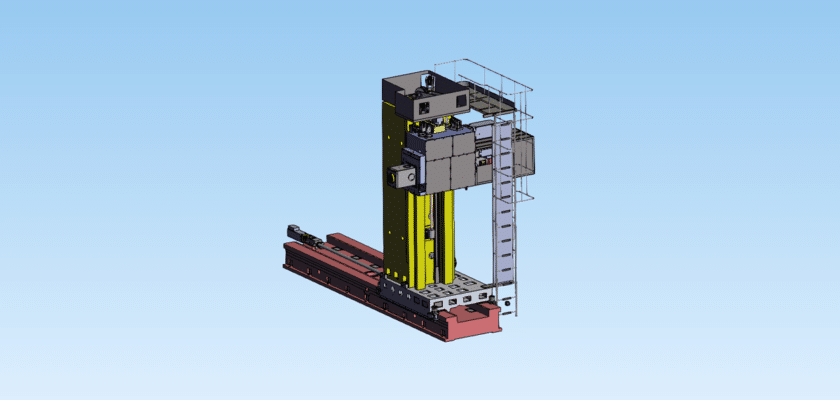

Master large-scale industrial fabrication by choosing to download our professional Heavy-Duty CNC Floor-Type Boring And Milling Machine drawing. For the processing of massive components such as power plant turbines, ship engine blocks, and aerospace structural members, the floor-type boring machine is the ultimate solution. This technical drawing provides a comprehensive architectural blueprint of the machine’s distinct floor-mounted layout, where the workpiece remains stationary on a heavy-duty floor plate while the massive column traverses alongside it. It is an essential asset for engineers specializing in extra-large part machining and facility layout planning.

By utilizing this detailed CAD resource, you can analyze the high-rigidity column construction and the advanced ram-style spindle head designed to maintain sub-millimeter accuracy even at full extension. The drawing covers the complex X-axis bed structures and the precision-ground guideways required to support the immense weight of the mobile column. Whether you are retrofitting a legacy boring mill or designing a modern automated machining cell for the energy sector, these schematics offer the foundational data needed for foundation load requirements, hydraulic counterbalancing systems, and multi-axis synchronization. Accessing this verified design ensures your team understands the mechanics behind one of the most powerful and versatile machine tools in existence.

Principais recursos:

- Independent Floor Plate Architecture: Detailed schematics for the modular T-slot floor plate system, designed to support workpieces weighing several hundred tons.

- Extended Ram-Type Spindle: Structural insights into the high-torque, telescoping ram design that provides deep-hole boring and milling capabilities with minimal deflection.

- Hydrostatic Guideway System: Specifications for the high-precision hydrostatic bearing surfaces that ensure smooth, friction-free movement of the massive column.

- Automatic Accessory Head Changer: Architectural details for the integration of universal, right-angle, and facing heads to perform complex multi-sided machining.

- Dual-Rack and Pinion Drive: Comprehensive layouts for the synchronized X-axis drive system, optimized for high-force transmission and backlash elimination over long travels.