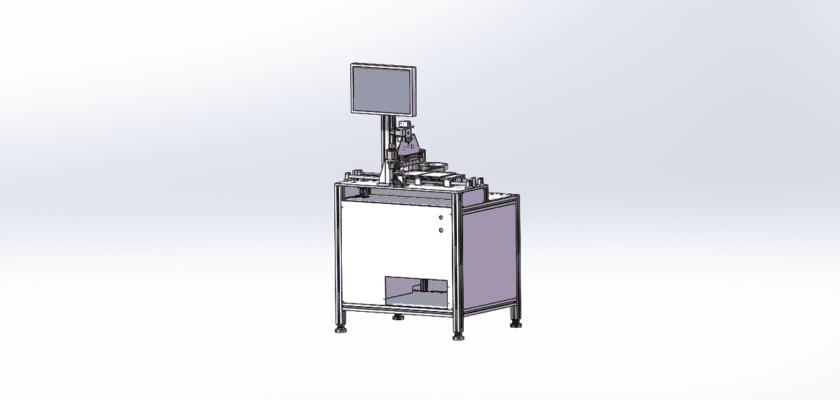

This detailed drawing of the High-Speed LED Component Placement Machine illustrates a cutting-edge system designed for the rapid and accurate placement of LED components on printed circuit boards (PCBs). Ideal for manufacturers in the electronics and lighting industries, this machine enhances productivity while ensuring high-quality assembly standards.

Principais características do desenho:

- High-Speed Automated Placement: The machine utilizes advanced automation technology to achieve rapid placement of LED components, significantly increasing throughput and reducing assembly time.

- Manuseio de componentes de precisão: Equipped with high-precision feeders and intelligent vision systems, the machine ensures accurate alignment and placement of LEDs, meeting stringent quality requirements.

- Multi-Head Configuration: Featuring multiple placement heads, the machine can handle several components simultaneously, optimizing workflow and enhancing overall efficiency in production.

- Interface de controle amigável: An intuitive control panel allows operators to easily program and monitor placement parameters, facilitating quick adjustments for different LED sizes and configurations.

- Recursos de Controle de Qualidade Integrados: Built-in inspection systems continuously monitor placement accuracy and component quality, ensuring that each assembled PCB meets industry standards and minimizing defects.

- Compatibilidade de aplicativos versáteis: Designed to accommodate a wide range of LED types, including surface-mounted and through-hole components, making it adaptable for diverse electronic applications.

- Construção robusta e durável:Construída com materiais de alta qualidade, a máquina foi projetada para longevidade e confiabilidade, garantindo desempenho ideal em ambientes de produção de alto volume.

This drawing serves as an essential reference for engineers and manufacturers seeking to implement effective and efficient LED component placement solutions in their assembly processes.