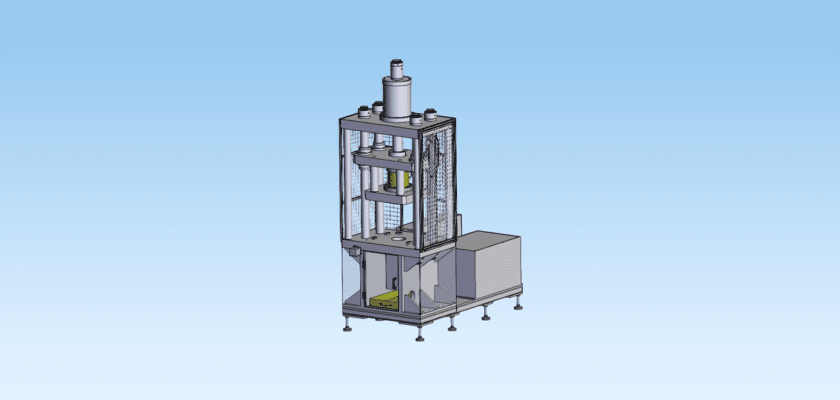

Pegue o incredible technical desenho set for a specialized Hydraulic Press For Punching Bosses! MechStream is offering these high-detail blueprints for download gratuito. This is an essential resource for tool and die makers, metal fabricators, and manufacturing engineers focused on sheet metal deformation and forming processes. This hydraulic press is specifically designed to apply high, controlled force necessary for accurately punching or forming bosses (raised features) into sheet metal components, which are crucial for subsequent assembly and fastening.

Our comprehensive package grants instant access to the ultimate design specifications of this powerful machinery. The desenho set includes detailed plans for the robust frame structure, the main hydraulic cylinder assembly, the moving platen, and the precision tooling interface. Understanding the force transmission path and the rigidity of the C-frame or H-frame design is key to ensuring consistent and accurate boss formation. By downloading these awesome technical files, you gain all the necessary dimensional data, material specifications, and assembly layouts for accurate manufacturing, modification, or in-depth study. Stop compromising on tooling accuracy. Download the complete Hydraulic Press For Punching Bosses drawing today and leverage professional-grade schematics to ensure your machine delivers high-quality, repeatable forming operations. This resource is indispensable for anyone in the metal forming industry.

Principais recursos:

- Design de estrutura de alta rigidez: Detailed structural drawings specifying material and joint construction to withstand high punching forces without deflection.

- Cylinder and Ram Assembly: Precise mounting and dimensional specifications for the main hydraulic cylinder and guided ram system, ensuring vertical accuracy.

- Tooling Interface Details: Plans for the bolster plate and ram surface, detailing T-slots or mounting patterns for attaching the boss punching dies.

- Hydraulic Control Schematic: Illustrates the circuit for controlling ram speed and applied tonnage, crucial for successful forming operations.

- Safety Mechanism Integration: Includes drawings for physical safety stops, light curtains, or guarding attachment points as required for press operation.