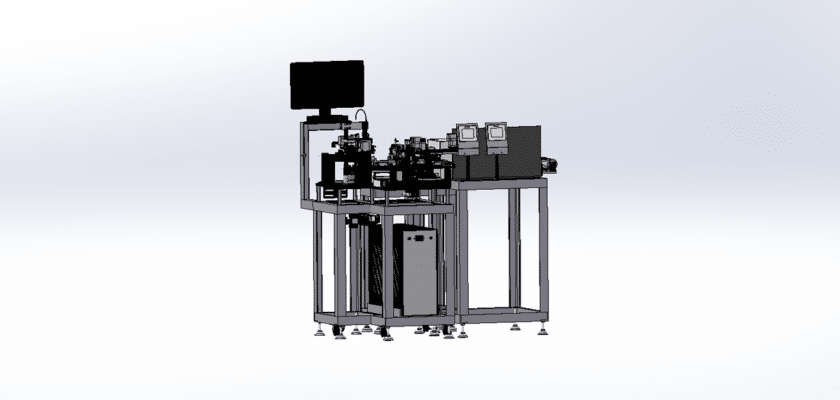

Este desenho detalhado da Máquina de Montagem, Soldagem e Colagem de Indutores ilustra um sistema sofisticado projetado para a montagem automatizada de indutores, integrando processos de soldagem e colagem para maior eficiência. Ideal para fabricantes da indústria eletrônica, esta máquina agiliza a produção e garante altos padrões de qualidade de montagem.

Principais características do desenho:

- Processo de Montagem Integrado:A máquina combina operações de montagem, soldagem e colagem em um único sistema automatizado, reduzindo o tempo de manuseio e otimizando o fluxo de trabalho.

- Manuseio de componentes de alta precisão: Equipado com braços robóticos avançados e dispositivos de precisão, o sistema garante alinhamento e montagem precisos dos componentes do indutor, atendendo a rigorosos padrões de qualidade.

- Mecanismo de Soldagem Automatizado:A estação de soldagem utiliza técnicas de alta precisão para unir com segurança as peças do indutor, fornecendo conexões fortes e confiáveis essenciais para o desempenho.

- Aplicação de colagem eficiente: Um sistema de colagem automatizado aplica o adesivo uniformemente, garantindo uma colagem consistente dos componentes e minimizando o uso excessivo de material.

- Interface de controle amigável: Um painel de controle intuitivo permite que os operadores programem e monitorem facilmente os parâmetros de montagem, facilitando ajustes rápidos para diferentes projetos e especificações de indutores.

- Recursos de Controle de Qualidade Integrados: Sistemas de inspeção integrados monitoram continuamente os processos de montagem, soldagem e colagem, garantindo que cada indutor atenda aos padrões de qualidade e minimizando defeitos.

- Construção robusta e durável:Construída com materiais de alta qualidade, a máquina foi projetada para longevidade e confiabilidade, garantindo desempenho ideal em ambientes de produção de alto volume.

Este desenho serve como referência essencial para engenheiros e fabricantes que buscam implementar soluções eficazes e eficientes para montagem, soldagem e colagem de indutores em suas linhas de produção.