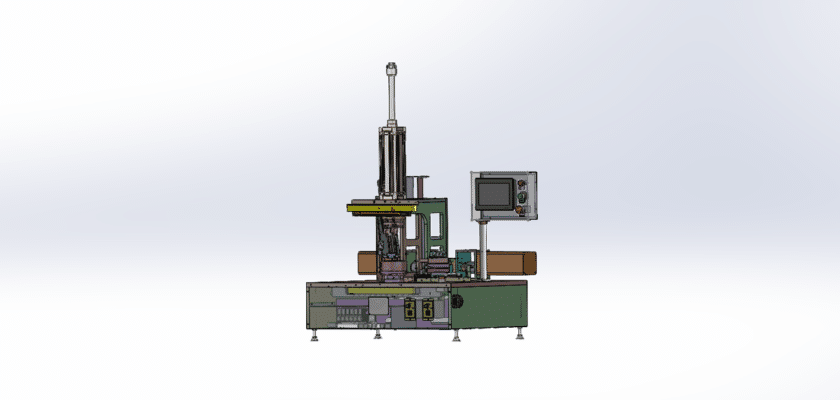

Este desenho detalhado da Máquina de Colagem de Anéis Internos e Externos ilustra um sistema especializado projetado para a colagem precisa de anéis internos e externos utilizados em diversas aplicações, incluindo rolamentos e conjuntos mecânicos. Ideal para fabricantes dos setores automotivo, aeroespacial e industrial, esta máquina aumenta a produtividade e garante uma colagem de alta qualidade.

Principais características do desenho:

- Processo de colagem automatizado:A máquina emprega tecnologia de automação avançada para agilizar a operação de colagem, aumentando significativamente a produtividade e reduzindo a necessidade de trabalho manual.

- Configuração de estação dupla: Com estações separadas para colagem de anéis internos e externos, o design otimiza o fluxo de trabalho e permite o processamento simultâneo, aumentando a eficiência geral.

- Sistema de Aplicação de Alta Precisão: Equipada com dispensadores de precisão, a máquina garante aplicação uniforme do adesivo, minimizando o desperdício e garantindo ligações fortes e confiáveis.

- Interface de controle amigável: Um painel de controle intuitivo permite que os operadores programem e monitorem facilmente os parâmetros de colagem, facilitando ajustes rápidos para diferentes tamanhos e materiais de anéis.

- Recursos de Controle de Qualidade Integrados: Sistemas de inspeção integrados monitoram continuamente o processo de colagem, garantindo que cada conjunto colado atenda aos padrões de qualidade e minimizando defeitos.

- Compatibilidade versátil com materiais: Projetado para acomodar vários tipos de adesivos e materiais de anel, tornando-o adaptável para diversas aplicações em vários setores.

- Construção robusta e durável:Construída com materiais de alta qualidade, a máquina foi projetada para longevidade e confiabilidade, garantindo desempenho ideal em ambientes de produção de alto volume.

Este desenho serve como referência essencial para engenheiros e fabricantes que buscam implementar soluções de colagem eficazes e eficientes para anéis internos e externos em suas linhas de produção.