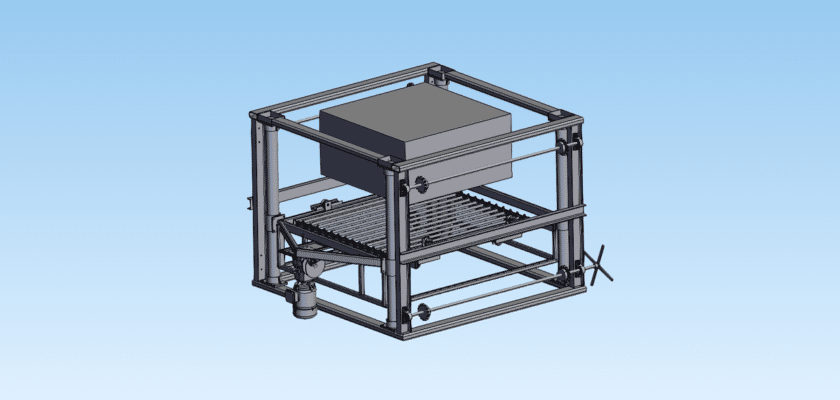

Optimize your heavy-duty fabrication workflow by choosing to download our professional Large CNC Cutting Machine Tool drawing. When dealing with oversized plates and high-volume material conversion, a large-format CNC cutting system is essential for maintaining both speed and dimensional accuracy. This technical drawing provides a comprehensive mechanical blueprint of a wide-span cutting platform, detailing the gantry architecture, rail synchronization, and the integration points for various cutting heads—whether plasma, oxy-fuel, or fiber laser. It is an indispensable resource for facility planners and machine designers looking to implement large-scale thermal or mechanical cutting solutions.

By utilizing this detailed CAD resource, your engineering team can analyze the structural requirements for the long-travel X-axis rails and the high-speed Y-axis gantry. The drawing offers deep insights into the rack-and-pinion drive systems and the cable management chains (drag chains) required to service a massive work envelope. Whether you are producing components for shipbuilding, heavy infrastructure, or large pressure vessels, these schematics provide the precise data needed for foundation leveling, fume extraction ducting, and multi-torch synchronization. Accessing this verified design allows you to scale your production capabilities while ensuring the long-term structural integrity of your cutting equipment.

Principais recursos:

- High-Stability Wide-Span Gantry: Detailed schematics for a reinforced bridge design that minimizes vibration and maintains torch height accuracy across widths exceeding 3 meters.

- Precision Synchronized Dual-Drive: Structural insights into the master-slave drive configuration that ensures perfectly square cutting across the entire length of the machine.

- Integrated Fume Extraction Layout: Architectural details for a downdraft table or water-bed interface, essential for maintaining air quality during high-power thermal cutting.

- Modular Torch Carriage Design: A versatile mounting system that allows for the quick installation of multiple torches or specialized marking tools.

- Heavy-Duty Rail Support System: Specifications for the floor-mounted or pedestal-supported H-beam rails, engineered to handle the dynamic loads of high-speed traverses.