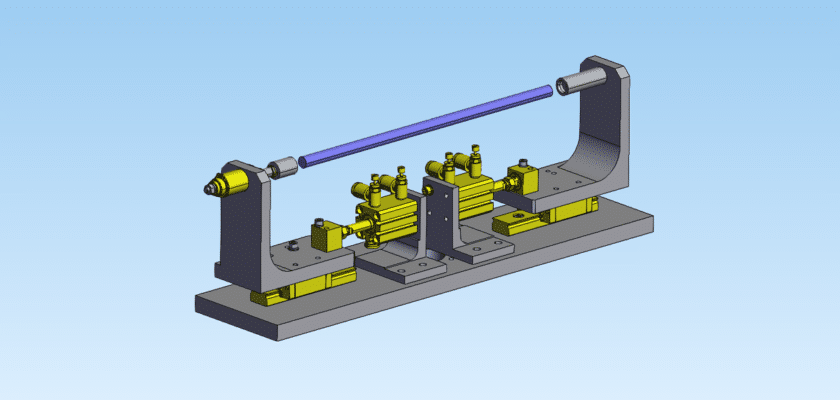

Maintaining axial straightness is the primary challenge when machining or assembling extended components, and our Long Workpiece Fixing Mechanism drawing provides the high-rigidity solution required. When the length-to-diameter ratio of a part is high, traditional end-clamping is insufficient to prevent “chatter” or permanent deformation under load. This technical CAD resource offers a comprehensive blueprint for a multi-point stabilization system, featuring both static and traveling support architectures. By downloading this file, you gain access to a design that ensures uniform clamping pressure along the entire length of the workpiece.

The design featured in this package focuses on the integration of Steady Rests e Follower Rests. The drawing includes detailed views of adjustable three-point contact rollers, hydraulic self-centering clamps, and vibration-dampening pads. By utilizing this blueprint from MechStream, you can eliminate “sag” caused by gravity and “whip” caused by high-speed rotation. This is an essential asset for designers of heavy-duty lathes, pipe welding rotators, and specialized milling fixtures for structural beams.

Our technical documentation prioritizes precision alignment and surface protection. The assembly is designed with non-marring roller materials and fine-thread adjustment screws to ensure that the fixing mechanism supports the part without scoring the finished surface. Whether you are building a custom jig for aerospace stringers or an automated grinding station for hydraulic rods, this drawing provides the exact geometric tolerances, material specifications, and load-bearing calculations required for professional-grade stability.

Principais recursos:

- Multi-Point Support Architecture: Engineered to distribute clamping forces evenly, preventing structural bowing in slender parts.

- Self-Centering Linkage: Features a synchronized three-point contact system that automatically finds the workpiece centerline.

- Anti-Vibration Dampening: Includes specialized polymer or bronze contact pads to absorb harmonic vibrations during high-speed operations.

- Modular Length Expansion: The design allows for the addition of multiple support units along a common base rail for extremely long workpieces.

- Quick-Release Clamping: Detailed specifications for toggle-action or pneumatic clamps that allow for rapid loading and unloading without manual recalibration.