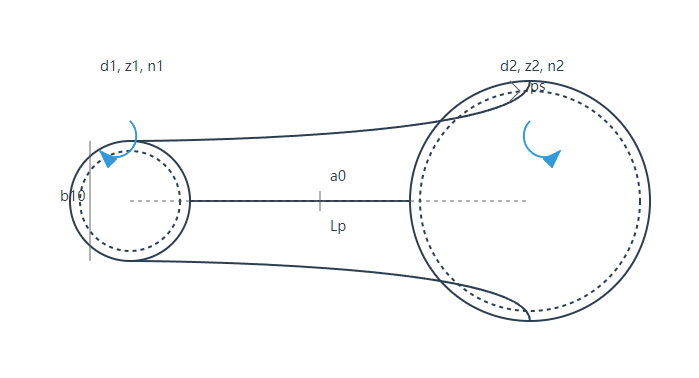

Explore a eficiência da nossa Calculadora de Redutores de Correia Síncronos de Passo Modular, projetada para otimizar seus projetos de engenharia com precisão e facilidade. Esta ferramenta oferece cálculos precisos para sistemas de redutores de correia, aprimorando a precisão do projeto e o desempenho operacional. Seja você um engenheiro mecânico ou um gerente de projeto, nossa calculadora fornece resultados confiáveis que agilizam processos e aumentam a produtividade. Experimente a sinergia da engenharia avançada e da interface amigável, atendendo a todas as suas necessidades de cálculo de redutores de correia síncronos.