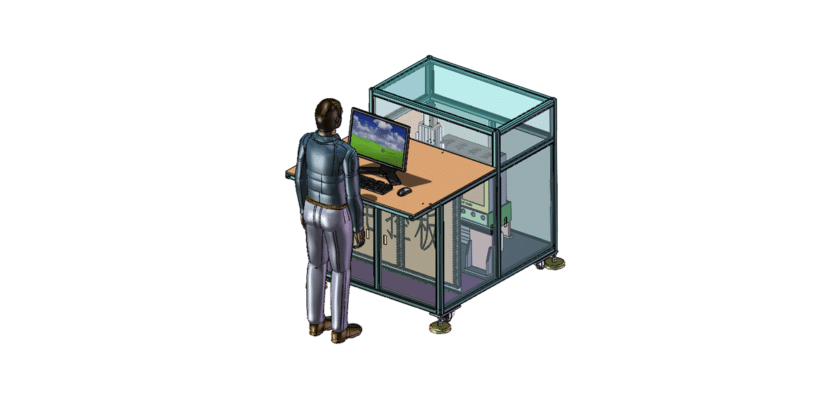

Um desenho de máquina de detecção visual de imagem de molde é uma ilustração técnica que descreve os componentes e o layout de uma máquina projetada para a inspeção visual automatizada de moldes usando tecnologia de imagem.

Principais recursos:

- Estação de Inspeção: Diagramas mostrando a área designada onde os moldes são colocados para inspeção, apresentando acessórios ou grampos para segurar os moldes com segurança durante o processo de avaliação.

- Sistema de Câmera: Representação de câmeras de alta resolução ou sensores de imagem que capturam imagens detalhadas dos moldes, incluindo seu posicionamento para cobertura e clareza ideais.

- Configuração de iluminação: Detalhes sobre o sistema de iluminação, como luzes LED ou retroiluminação, que melhoram a visibilidade das superfícies do molde e destacam quaisquer defeitos ou imperfeições.

- Unidade de Processamento de Imagem: Informações sobre a unidade de processamento que analisa as imagens capturadas usando algoritmos avançados para detectar defeitos, medir dimensões e avaliar a qualidade geral do molde.

- Interface do usuário: Ilustrações do painel de controle ou tela sensível ao toque que permite aos operadores monitorar o processo de inspeção, ajustar configurações e visualizar resultados em tempo real.

- Sistemas de saída de dados: Diagramas mostrando como os resultados da inspeção são comunicados e registrados, incluindo displays digitais para feedback imediato, relatórios para controle de qualidade e conexões com sistemas de gerenciamento de dados para análise posterior.

- Sistema de Manuseio Mecânico: Informações sobre as correias transportadoras ou braços robóticos que transportam os moldes pela área de inspeção, garantindo um processamento eficiente e minimizando erros de manuseio.

- Fonte de energia: Detalhes sobre os requisitos de energia, incluindo conexões elétricas e quaisquer sistemas de backup para manter uma operação consistente.

Este desenho serve como uma referência abrangente para engenheiros e técnicos envolvidos no projeto, montagem e manutenção de máquinas de detecção visual de imagens de moldes, garantindo altos padrões de controle de qualidade e eficiência operacional nos processos de fabricação.