Standardize your quality control for non-ferrous components with our professional Inspection of Non-Magnetic Cylindrical Workpieces drawing. When working with materials like aluminum, copper, or advanced ceramics, engineers cannot rely on magnetic bases for stability or inductive sensors for detection. This technical CAD resource provides a comprehensive blueprint for a specialized metrology fixture designed to hold, rotate, and measure non-magnetic cylinders with sub-micron precision. By downloading this file, you gain access to a design that prioritizes mechanical centering and low-friction rotation to ensure accurate TIR (Total Indicator Reading) and roundness profiles.

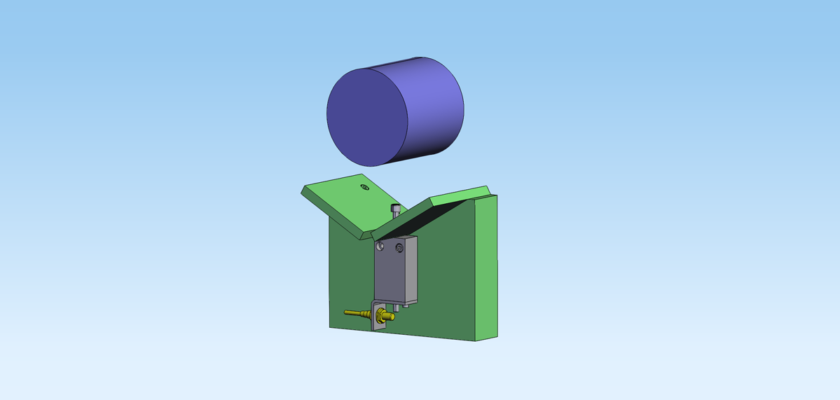

The design featured in this package focuses on the Three-Point Contact or Air-Bearing architecture. The drawing includes detailed views of precision-ground carbide V-blocks or specialized rollers that support the workpiece without marring its surface. Since the parts are non-magnetic, the assembly features an adjustable overhead pressure roller or a vacuum-assisted lockdown to ensure the part remains seated during high-speed rotation. By utilizing this blueprint from MechStream, you can accurately measure run-out, taper, and diameter on critical components like printer rollers, aluminum drive shafts, and medical tubing.

Our technical documentation prioritizes sensor compatibility and environmental isolation. The assembly is designed to integrate non-contact sensors—such as laser triangulation displacement sensors or capacitive probes—which are essential for non-conductive or non-magnetic materials. Whether you are building a manual inspection bench or a fully automated robotic gauging cell, this drawing provides the exact material specifications, bearing tolerances, and sensor mounting geometries required for a professional-grade metrology installation.

Principais recursos:

- Universal Non-Magnetic Support: Engineered with non-ferrous materials (300-series stainless, granite, or polymer) to prevent interference with sensitive eddy-current or capacitive sensors.

- Precision Rotary Drive: Includes schematics for a friction-drive or belt-drive system that rotates the workpiece without the need for magnetic clamping.

- Multi-Probe Metrology Bridge: Features a modular rail system for mounting multiple displacement probes to check for taper and straightness in a single rotation.

- Non-Marring Contact Points: Detailed specifications for specialized roller bearings or air-bearings that protect the surface finish of delicate aluminum or plastic parts.

- Integrated Centering Adjustment: Features a micro-adjustable tailstock to ensure the workpiece is perfectly coaxial with the measurement sensors.