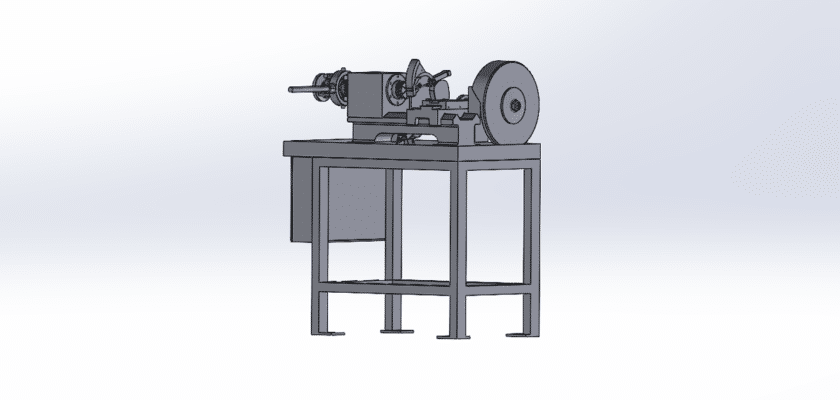

This detailed drawing of the Non-Standard Special Machine illustrates a specialized system designed to meet unique operational requirements that do not conform to standard machinery specifications. Ideal for industries such as automotive, aerospace, and custom fabrication, this machine enhances production capabilities while ensuring precision and efficiency.

Principais características do desenho:

- Design personalizável: Engineered to accommodate a wide range of specific tasks, the machine can be tailored to fulfill unique manufacturing needs and adapt to various production processes.

- Funcionalidade Versátil: Equipped with multi-functional capabilities, the machine can perform diverse operations such as machining, assembly, and testing, streamlining workflow and reducing the need for multiple machines.

- Engenharia de Precisão: High-accuracy components ensure that operations are executed with precision, minimizing the risk of errors and improving overall product quality.

- Sistema de controle de fácil utilização: An intuitive control panel allows operators to easily configure settings, monitor performance, and quickly adjust parameters for different applications.

- Construção robusta e durável: Constructed from high-quality materials, the machine is designed for long-lasting reliability, ensuring consistent performance in demanding production environments.

- Recursos de segurança integrados: The design includes safety mechanisms, such as emergency stops and protective enclosures, to safeguard operators during operation.

- Adaptable to Various Materials: Capable of handling a wide range of materials and product types, the machine is suitable for diverse applications across multiple sectors.

- Manuseio eficiente de materiais: The machine may include automated feeding and positioning systems, enhancing production efficiency and workflow.

This drawing serves as a vital reference for engineers and manufacturers seeking innovative and effective solutions for non-standard special machinery applications in their production processes.