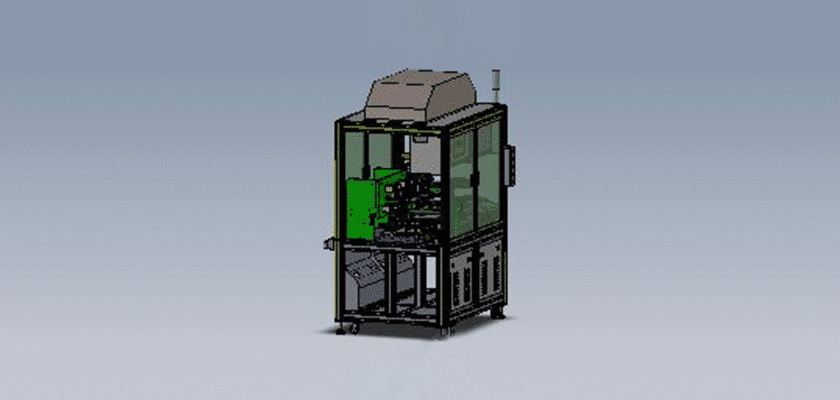

Unlock the precision of display manufacturing with our free technical drawings of an Máquina de colagem OGS. This highly specialized equipment is the cornerstone of modern touch screen production, where the touch sensor is directly integrated onto the cover glass, eliminating the need for a separate touch panel. The blueprints reveal a complex, automated system designed to perform high-precision, cleanroom-level bonding of these delicate components. This process is critical for achieving the slim profiles and superior optical clarity required for smartphones, tablets, and other high-end displays.

This drawing package is an essential resource for students of mechatronics, professionals in display technology, and engineers interested in advanced automation. By studying these plans, you will gain a deep understanding of the challenges of handling fragile materials, controlling vacuum pressure, and achieving perfect alignment on a microscopic scale. Download this invaluable resource now to accelerate your path to more advanced and efficient manufacturing techniques and gain a competitive edge in your field.

Principais recursos:

- High-Precision Alignment: The drawings detail a sophisticated system using vision cameras and robotic arms to achieve perfect alignment between the glass and the touch sensor.

- Vacuum Bonding Chamber: Blueprints highlight the design of the vacuum chamber, essential for removing air bubbles and ensuring a flawless, optically clear bond.

- Automated Material Handling: The plans illustrate the mechanisms for feeding and unloading delicate glass panels without damage.

- Integrated Control Systems: The drawings provide insight into the sensors and control logic required to manage the complex, multi-step bonding process.