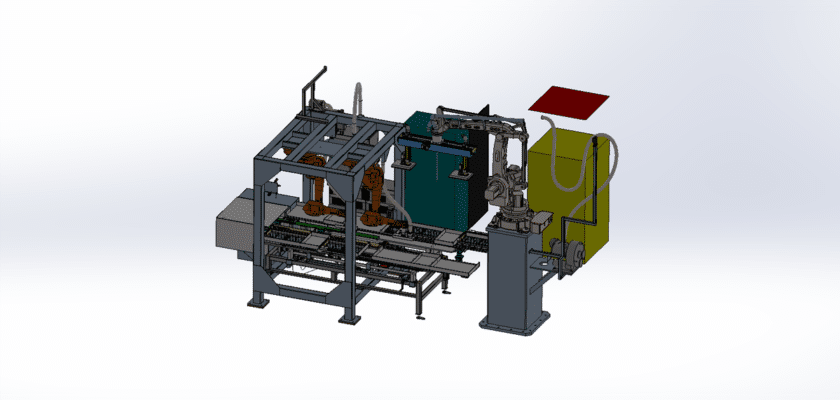

O desenho da Linha de Correias Transportadoras para Banheiros da P&G fornece um esquema detalhado de um sistema transportador projetado especificamente para o manuseio e transporte eficientes de produtos de banheiro em um ambiente de fabricação ou embalagem. Esta linha de correias personalizada é adaptada para atender aos requisitos operacionais exclusivos da Procter & Gamble (P&G) e indústrias similares, aprimorando a produtividade e o fluxo de trabalho.

Principais recursos:

- Layout do transportador: O desenho ilustra a configuração geral da linha de correias transportadoras, mostrando seu comprimento, largura e quaisquer inclinações ou curvas necessárias. O projeto é otimizado para o transporte suave de produtos, garantindo transições eficientes entre as diversas etapas do processo de montagem ou embalagem.

- Especificações da correia: São fornecidas informações detalhadas sobre o material da correia transportadora, incluindo composição (por exemplo, PVC, borracha), dimensões e textura da superfície. A correia foi projetada para acomodar os tipos específicos de produtos de banheiro, garantindo um transporte seguro e minimizando o desgaste do produto.

- Mecanismo de acionamento: Inclui uma visão geral do sistema de acionamento, detalhando o motor elétrico, as polias e os sistemas de engrenagens que alimentam o transportador. Especificações sobre a potência do motor, classificações de torque e mecanismos de tensionamento da correia são fornecidas para garantir um desempenho confiável sob cargas variadas.

- Estrutura de suporte: A estrutura robusta e o sistema de suporte são mostrados, enfatizando a estabilidade e a durabilidade para suportar o peso dos produtos de banho durante o transporte. O projeto incorpora avaliações estruturais para garantir a operação segura durante todo o uso do transportador.

- Recursos de segurança: Componentes essenciais de segurança, como botões de parada de emergência, proteções de segurança e sensores para detecção de desalinhamento ou sobrecarga, são claramente marcados para aumentar a segurança do operador e garantir a conformidade com os padrões de segurança do setor.

- Sistemas de Controle: São fornecidas informações sobre os mecanismos de controle usados para monitorar e regular a operação do transportador, incluindo interfaces fáceis de usar para ajustes de velocidade e indicadores de status operacional.

- Recursos de movimentação de materiais: O design pode incorporar recursos adicionais, como grades laterais, sistemas de guia ou zonas de acumulação para garantir o alinhamento adequado dos produtos e evitar deslizamentos durante o transporte.

- Acessibilidade de Manutenção: O desenho inclui considerações para fácil acesso a componentes críticos para manutenção de rotina e inspeções, promovendo manutenção eficiente e minimizando o tempo de inatividade.

Este desenho serve como um recurso vital para engenheiros, gerentes de produção e pessoal de manutenção, oferecendo insights abrangentes sobre o projeto, implementação e operação da linha de correias transportadoras para banheiros da P&G em diversas aplicações de fabricação.