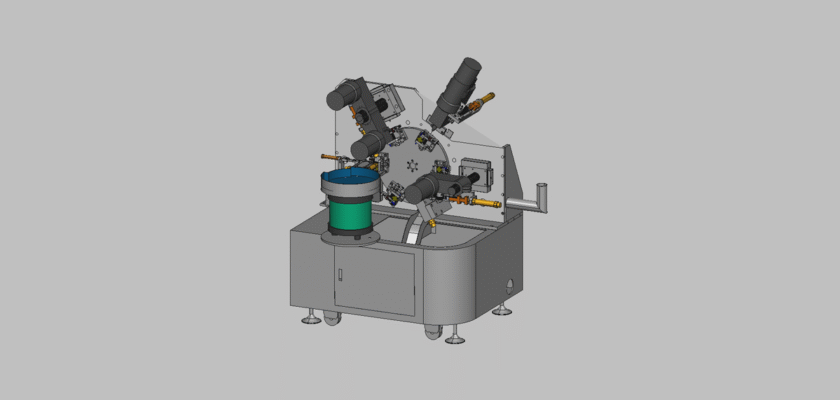

Unlock unparalleled precision in your electronics manufacturing with our free Fully Automatic Precision PIN Drilling Machine drawing. This detailed CAD file is an essential resource for engineers and manufacturers in the electronics and aerospace industries. The drawing provides a comprehensive look at a specialized machine designed to automatically drill tiny, high-tolerance holes for pins in printed circuit boards (PCBs) or other components. This crucial process ensures perfect alignment and reliable connections, which is vital for the performance of high-density electronic assemblies.

The blueprint highlights the machine’s complex mechanisms, including the automated loading system, the high-speed spindle, and the vision-guided positioning system that ensures pinpoint accuracy. Understanding these components is critical for achieving high-volume production with minimal defects. The design is optimized for continuous, high-speed operation and is compatible with a wide range of component sizes and materials. Whether you are building a new drilling station, upgrading existing equipment, or studying the principles of industrial automation, this drawing provides the technical insights you need. It’s a perfect tool for students and professionals alike, offering a detailed glimpse into the future of high-precision micro-machining.

Principais recursos:

- Perfuração automatizada: The drawing details a system for automatically loading and drilling components, which is crucial for high-speed production.

- Fuso de alta precisão: It showcases the design of a high-speed spindle that is engineered for drilling micro-holes with exceptional accuracy.

- Vision-Guided System: The blueprint illustrates the use of a vision system to precisely align the components before drilling, ensuring perfect hole placement.

- Produção de alto volume: O layout da máquina é otimizado para operação rápida e contínua, tornando-a ideal para produção em massa.

- Especificações técnicas: Inclui dimensões e especificações críticas para os componentes da máquina, tornando-a adequada para fins de design e referência.