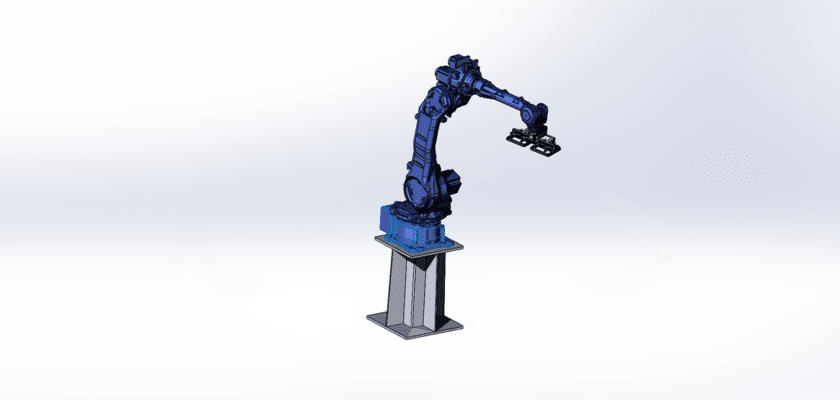

A Robot Loading and Unloading Equipment Drawing is a detailed technical illustration that depicts the design, components, and operational workflow of a robotic system specifically engineered for automating the loading and unloading of materials, components, or products. This drawing is essential for engineers, operators, and technicians involved in the development, operation, and maintenance of automated handling systems.

Principais recursos:

- Layout geral: A comprehensive view of the loading and unloading system, showcasing the arrangement of robotic arms, conveyors, and storage or processing areas within the operational environment.

- Braços Robóticos: Detailed illustrations of the robotic arms used for loading and unloading tasks, including:

- Configuração do braço: Information about the structure, links, and joints of the robotic arms, highlighting their degrees of freedom to facilitate flexible and precise movements.

- Efetores finais: Descriptions of specialized tools or grippers designed for handling various materials, such as suction cups, forks, or custom clamps, tailored for specific applications.

- Loading and Unloading Mechanisms: Diagrams illustrating the processes involved in loading and unloading, including:

- Sistemas de transporte: Details on conveyor belts or automated guided vehicles (AGVs) that transport materials to and from the robotic station.

- Orientation and Positioning Systems: Information on mechanisms that ensure materials are correctly oriented for efficient loading or unloading.

- Sistemas de Controle: Information about the central control unit managing the robotic operations, including:

- Controladores Lógicos Programáveis (CLP): Descriptions of PLCs or industrial computers that coordinate the movements of the robot and material handling processes.

- Interface do usuário: Illustrations of control panels or software interfaces that allow operators to program tasks, monitor system performance, and make adjustments.

- Recursos de segurança: Informações sobre mecanismos de segurança integrados ao sistema, tais como:

- Sistemas de parada de emergência: Easily accessible emergency stop buttons located near the loading and unloading stations.

- Protetores e sensores de segurança: Informações sobre barreiras de proteção, cortinas de luz e sensores projetados para aumentar a segurança do operador durante a operação.

- Material Handling Systems: Illustrations of systems used to transport materials to and from the loading and unloading stations, including:

- Automated Storage and Retrieval Systems (AS/RS): Systems that facilitate efficient storage and retrieval of items.

- Forklifts or Pallet Jacks: Information on additional equipment that may be used in conjunction with robotic systems.

- Quality Control Measures: Descriptions of integrated quality control systems, including:

- Estações de Inspeção: Information on sensors or cameras that verify the accuracy of loaded or unloaded items.

- Equipamento de teste: Details on any testing apparatus used to ensure the quality and integrity of materials being handled.

- Pontos de acesso de manutenção: Guidance on areas designed for easy access during maintenance and repair, facilitating efficient servicing of the robotic equipment.

- Especificações de desempenho: Summary of key performance metrics, such as loading and unloading speeds, accuracy, and operational efficiency, providing essential information for process optimization.

- Contexto da aplicação: Brief descriptions of typical applications for loading and unloading systems across various industries, including manufacturing, warehousing, logistics, and food processing.

This drawing serves as a vital reference for anyone involved in the design, operation, and maintenance of robotic loading and unloading systems, ensuring effective performance, reliability, and adherence to industry standards in automated material handling.