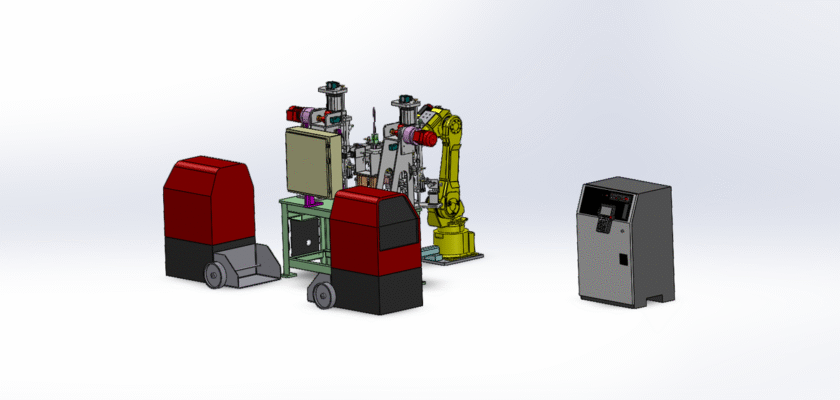

UM robotic automatic welding machine is an essential piece of equipment in modern manufacturing, delivering exceptional precision and speed in joining metal components. Unlike manual welding, these systems use a programmable robotic arm to execute complex weld paths, ensuring superior consistency and quality across every part. They are crucial for industries like automotive, aerospace, and construction, where high-strength, flawless welds are non-negotiable. This free drawing download provides a comprehensive look at the intricate design of a professional-grade welding automaton. It’s an invaluable resource for mechanical engineers, technicians, and students interested in industrial automation. By examining these blueprints, you will gain an understanding of how to enhance production efficiency, reduce labor costs, and improve safety by automating hazardous welding tasks. This drawing package can be used to plan a new fabrication facility, upgrade existing machinery, or simply for educational purposes.

Principais recursos:

- Consistência de solda excepcional: The robotic arm is programmed to follow a precise path and maintain optimal parameters, eliminating human error and ensuring uniform, high-quality welds on every single component.

- Maior velocidade de produção: The machine operates continuously without fatigue, drastically reducing cycle times and allowing for a higher throughput of finished products, which boosts overall factory output.

- Segurança aprimorada: The design incorporates robust safety measures, including protective barriers and sensors, to remove human operators from hazardous welding environments and reduce the risk of injury from fumes, heat, and sparks.

- Versátil e adaptável: Os planos oferecem suporte à integração de vários processos de soldagem, como MIG, TIG e soldagem a ponto, e podem ser personalizados para trabalhar com uma ampla variedade de materiais e geometrias de peças.

- Sistema de Controle Avançado: The drawings detail the control unit’s interface, which allows for easy programming of complex welding sequences and real-time monitoring of the entire process for quality assurance.