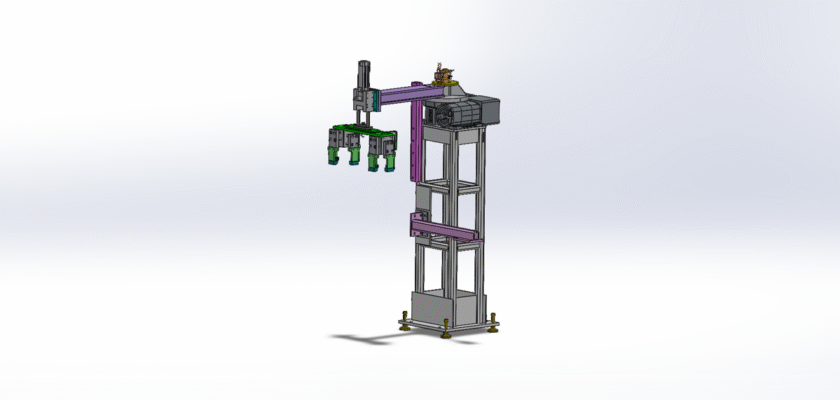

UM mecanismo de preensão robótico, também conhecido como pinça ou efetor final, é a "mão" de um braço robótico, permitindo que ele agarre, segure e manipule objetos. Esses mecanismos são um elo vital entre a programação do robô e o mundo físico, permitindo a automação em inúmeras indústrias, desde a montagem de eletrônicos de precisão até o manuseio de materiais pesados. O design de uma pinça é crucial e depende inteiramente da aplicação específica, considerando fatores como o formato, o tamanho, o peso e a fragilidade do objeto. Ao baixar este desenho abrangente, você obterá insights sobre o intrincado projeto mecânico de um mecanismo de preensão de nível profissional. É um recurso essencial para estudantes, engenheiros e entusiastas do "faça você mesmo" que desejam entender os princípios da manipulação robótica. Os planos detalham os componentes e sua interação, ajudando você a replicar o design ou criar sua própria solução personalizada para um projeto de automação.

Principais recursos:

- Design versátil para os dedos: O desenho apresenta uma configuração de dedos altamente adaptável que pode segurar com segurança objetos de vários formatos e tamanhos, tornando a pinça adequada para uma ampla gama de tarefas.

- Sistema de Atuação Preciso: Os projetos detalham um sistema de atuação avançado, proporcionando movimento suave e controlado. Essa precisão é fundamental para manusear componentes delicados sem causar danos.

- Compacto e leve: O design enfatiza um tamanho pequeno e baixo peso, o que é essencial para maximizar a capacidade de carga útil e a velocidade do braço do robô sem comprometer a força de preensão.

- Construção modular: A pinça foi projetada com uma abordagem modular, permitindo fácil substituição de peças ou personalização dos dedos para atender diferentes aplicações, aumentando assim sua flexibilidade e longevidade.