Jumpstart your automation projects with a vital Robotic Welding Workstation drawing set, available for download gratuito right now on MechStream. Implementing a robotic welding cell requires precise planning and layout to maximize efficiency, safety, and throughput. This comprehensive collection of Desenho CAD files provides the essential technical documentation needed to design, install, or modify automated welding setups. Whether you’re configuring a new manufacturing line or upgrading existing manual processes, these drawings are an indispensable resource for system integrators, mechanical engineers, and production managers.

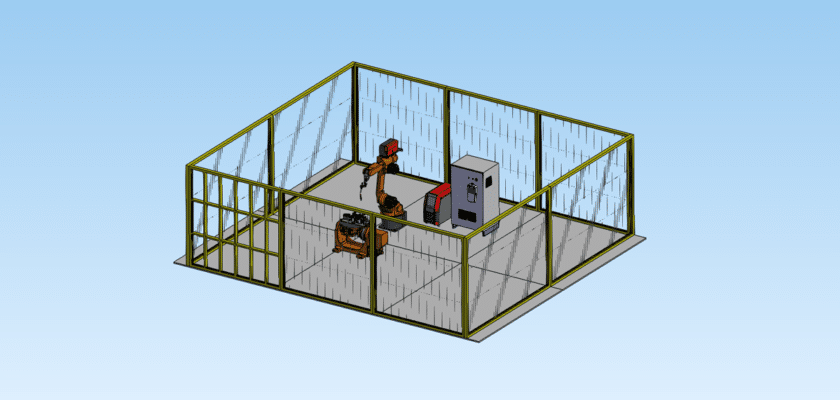

O Robotic Welding Workstation designs detail critical elements like robot arm positioning, safety enclosure dimensions, fixture tables, and peripheral equipment placement. Utilizing these accurate Desenho CAD files ensures that your final installation meets all ergonomic and safety standards, particularly concerning robotic reach and operational clearances. Detailed schematics help you accurately map out cable management, power supply, and control panel integration, minimizing installation errors and commissioning time. Automation is the future of manufacturing, and having the precise workstation drawing resources is key to a successful deployment. Download these crucial technical files immediately to enhance your design verification process, streamline fabrication, and achieve unparalleled consistency in your welding operations.

Principais recursos:

- Optimized Layouts: Includes pre-engineered configurations showing efficient placement of the robot, positioner, and safety light curtains.

- Component Details: Provides dimensional specifications for the welding fixture table and the cell’s structural components.

- Integração de segurança: Details the placement and design of safety enclosures and access points, adhering to modern industrial standards.

- Flow Efficiency: Helps visualize material handling paths (infeed/outfeed) to ensure maximum production efficiency.

- Design escalável: Drawings are adaptable, allowing engineers to scale the workstation to fit various part sizes and production volumes.