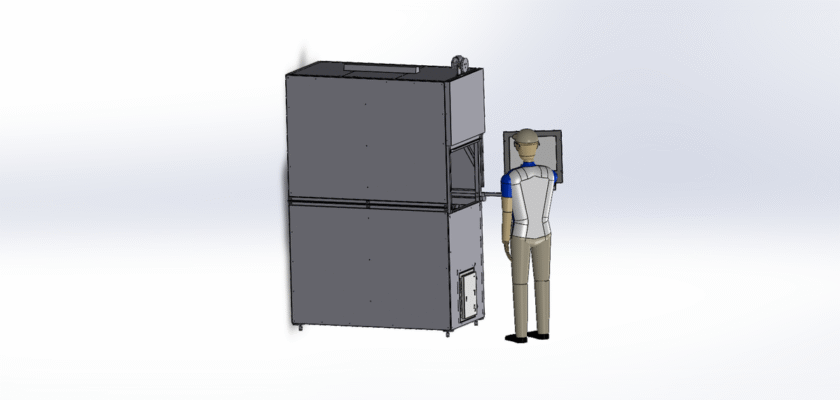

UM pequeno empilhador vertical é uma máquina compacta e compacta, projetada para levantar e empilhar materiais verticalmente, normalmente em uma linha de produção ou em um ambiente de armazenagem de pequena escala. Esta máquina é essencial para otimizar o espaço limitado, permitindo que os produtos sejam empilhados com eficiência, preparando-os para armazenamento, embalagem ou processamento posterior. Ao contrário de empilhadeiras ou transportadores grandes e tradicionais, o tamanho compacto e a operação simples de uma empilhadeira vertical a tornam ideal para integração em espaços apertados e linhas de montagem automatizadas. O desenho completo disponível para download gratuito fornece um projeto detalhado de uma empilhadeira vertical de nível profissional. Este recurso é inestimável para engenheiros mecânicos, planejadores de logística e estudantes que desejam entender os complexos sistemas mecânicos e pneumáticos que permitem o movimento vertical. Ao estudar esses projetos, você pode obter uma compreensão mais profunda de como essas máquinas são projetadas para lidar com diversas cargas e melhorar a eficiência de uma instalação.

Principais recursos:

- Tamanho compacto: O design foi desenvolvido para exigir o mínimo de espaço, o que o torna ideal para integração em linhas de produção ou áreas de armazenamento lotadas.

- Mecanismo de elevação vertical: O desenho detalha um sistema de elevação robusto, geralmente usando uma corrente, correia ou cilindro pneumático, para mover produtos para cima e para baixo com precisão e segurança.

- Empilhamento automatizado: Os projetos mostram um sistema com sensores e controles que podem empilhar produtos automaticamente em uma altura predefinida, garantindo consistência e precisão.

- Modular e adaptável: A natureza modular do design permite fácil personalização para acomodar diferentes tamanhos de produtos e alturas de empilhamento, proporcionando flexibilidade para diversas aplicações.