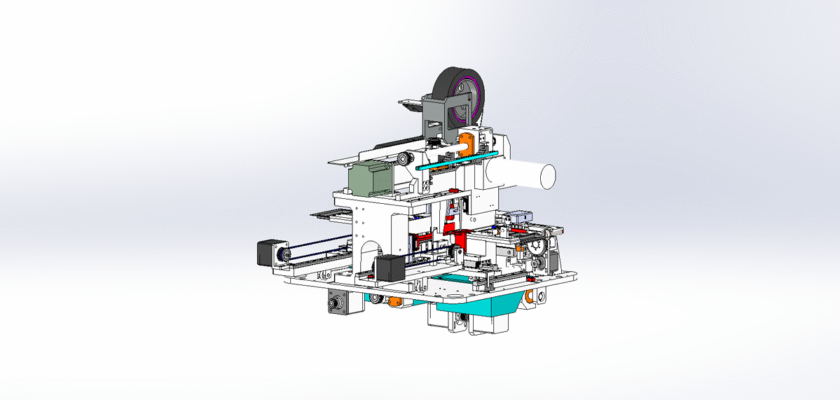

Aumente sua produção de tecnologia de montagem em superfície (SMT) com nossa desenho gratuito de emenda automática SMTEste arquivo CAD abrangente é um recurso inestimável para engenheiros, designers e fabricantes que trabalham com montagem eletrônica. Componente essencial de uma linha SMT moderna, a máquina de emenda é usada para unir de forma rápida e confiável uma nova bobina de componentes a uma antiga, permitindo a operação contínua e ininterrupta de máquinas pick-and-place. Isso é essencial para maximizar o tempo de atividade da máquina e a eficiência geral da produção.

O projeto fornece uma análise técnica completa do projeto da máquina de emenda, destacando seu mecanismo de alinhamento preciso, sistema de fixação robusto e cortador de fita automatizado. Compreender esses componentes é essencial para quem deseja construir uma ferramenta personalizada, integrá-la a uma nova linha ou simplesmente aprender sobre a complexa mecânica da automação SMT. Seja você um estudante de fabricação eletrônica, um profissional que busca otimizar sua produção ou uma empresa em busca de uma referência confiável, este desenho é a ferramenta perfeita para orientar seu próximo projeto. Baixe agora mesmo para acelerar seu processo de design ou simplesmente para aprender sobre o funcionamento interno deste equipamento essencial.

Principais recursos:

- Emenda automatizada de fitas: O desenho detalha a função principal da máquina de unir automaticamente fitas de componentes SMT para produção contínua.

- Alinhamento de precisão: Ele mostra o design do mecanismo de alinhamento que garante uma emenda perfeita e segura todas as vezes.

- Sistema de Corte Integrado: O projeto inclui o layout do cortador automatizado que corta o excesso de fita, preparando o novo rolo para a máquina pick-and-place.

- Design de alta eficiência: A máquina foi projetada para operação contínua e de alta velocidade, o que é essencial para minimizar o tempo de inatividade em uma linha SMT.

- Especificações técnicas: Inclui dimensões e especificações críticas para os componentes da máquina, tornando-a adequada para fins de design e referência.