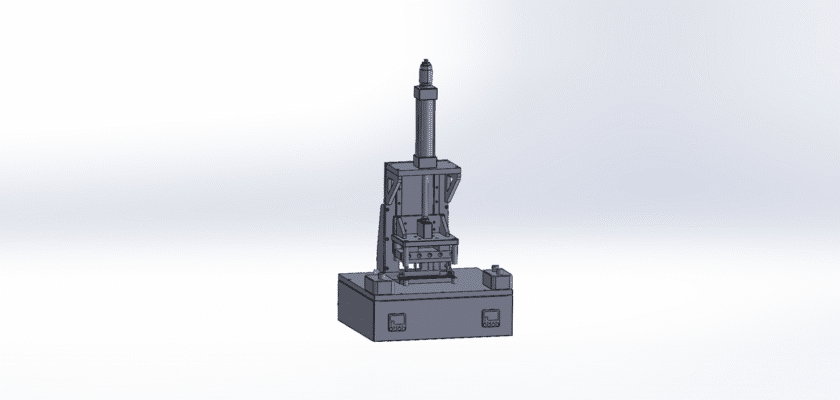

UM sophisticated hot melt machine is an advanced industrial system that precisely heats and dispenses thermoplastic adhesives for a wide range of applications, including packaging, product assembly, and bookbinding. Unlike basic glue guns, these machines feature an integrated system of tanks, pumps, hoses, and nozzles to ensure consistent temperature control and a continuous, clean application of adhesive. This technology is critical for high-speed production lines where a reliable and strong bond is essential for product quality and integrity. This comprehensive drawing, available for free download, provides a detailed blueprint of a professional-grade hot melt machine. It is an invaluable resource for mechanical engineers, packaging specialists, and students who want to understand the intricate thermal and hydraulic systems that make this equipment so effective. By studying these plans, you will gain a deeper understanding of how these machines are engineered to deliver a perfect bead of adhesive every time.

Principais recursos:

- Controle de temperatura de precisão: The drawing details a sophisticated heating system with multiple thermostats to maintain the adhesive at an optimal viscosity, ensuring a consistent and strong bond without overheating.

- Continuous Dispensing System: The blueprints showcase a pump and hose network designed for high-volume, continuous operation, which is essential for high-speed production lines.

- Modular Nozzle Design: The machine features a versatile nozzle system that can be easily changed to accommodate different application patterns, from fine lines to wide sprays, making it highly adaptable.

- Recursos de segurança integrados: The design includes safety interlocks and insulation to protect operators from high temperatures and pressures, ensuring a safe working environment.