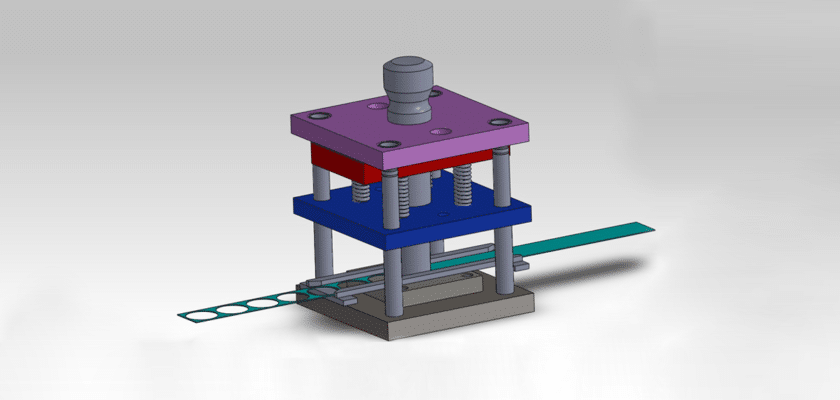

Precision begins at the point of impact with our Stamping Die Punch technical drawing. As the primary component responsible for shearing, piercing, or forming the workpiece, the punch must withstand immense compressive forces and abrasive wear. This CAD desenho provides a detailed blueprint of professional-grade punch designs, ranging from standard straight-shank piercing punches to complex profiled forming heads. By downloading this resource, you gain access to proven geometry that ensures clean cuts and maximizes intervals between regrinding.

This download provides a deep dive into the engineering behind punch stability and longevity. The layout includes specific tolerances for the punch-to-die clearance—a critical factor in determining the quality of the sheared edge and the reduction of burrs. You will also find detailed views of various retention methods, including “ball-lock” and “set-screw” retainers, which allow for rapid replacement during production. Whether you are working with high-strength steels or delicate aluminum alloys, this desenho provides the metallurgical recommendations and surface finish specs (such as DLC or TiN coating notes) needed to prevent galling and premature failure. At MechStream, we focus on the fine details that keep your press lines running.

Principais recursos:

- Optimized Shear Geometry: Includes specifications for “rooftop” or “concave” shear faces to reduce press tonnage and dampen noise.

- Precision Shank Fit: Detailed tolerances for the punch-to-holder interface to ensure absolute concentricity during high-speed strokes.

- Slug-Control Features: Features integrated vacuum holes or mechanical “ejector pins” to prevent slug pulling and die damage.

- Hardened Tool Steel Specs: Technical callouts for premium steels like A2, D2, or M2, including heat-treatment and hardness (HRC) guidelines.

- Advanced Coating Callouts: Recommended surface treatments to reduce friction and extend tool life in high-volume applications.