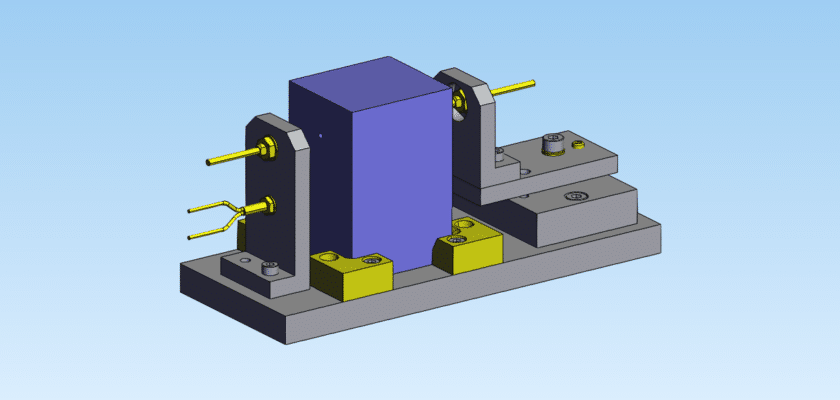

Discover a robust approach to orientation control with our Angle Adjustment Mechanism Using Steel Balls mechanical drawing. This specialized indexing design utilizes high-precision steel balls seated within machined detents to provide discrete, repeatable angular settings. Unlike standard friction-based pivots that may slip under heavy vibration or load, the ball-detent architecture ensures a positive mechanical lock at specific increments. This mechanism is an ideal solution for adjustable sensor mounts, heavy-duty camera stands, and modular tooling plates where stability and user-friendly adjustment are paramount.

The technical documentation provided details the critical spring-loading tension and the specific geometry of the indexing plate required for a smooth “click-into-place” operation. It outlines material specifications for the chrome steel balls and the hardened raceways to prevent galling or premature wear over thousands of cycles. By downloading this CAD resource, you gain access to a proven design that balances tactile feedback with high load-bearing capacity. Whether you are designing a manual adjustment knob or an automated indexing head, this blueprint provides the tolerances and assembly sequences needed to achieve a zero-backlash feel in your final product.

Principais recursos:

- Positive Incremental Indexing: Utilizes a detent-based system that allows for precise, repeatable angle steps with a secure, mechanical lock at every position.

- High-Hardness Contact Points: Includes specifications for hardened steel balls and seat inserts to ensure long-term durability and resistance to surface deformation.

- Adjustable Preload Tension: Detailed schematics for a spring-loaded adjustment screw, allowing the user to customize the tactile force required to change angles.

- Low-Profile Compact Design: Engineered to provide significant angular holding power within a slim, space-saving mechanical envelope.

- Self-Centering Geometry: The hemispherical interface of the steel balls ensures the mechanism naturally centers itself within each index point, eliminating mechanical slop.