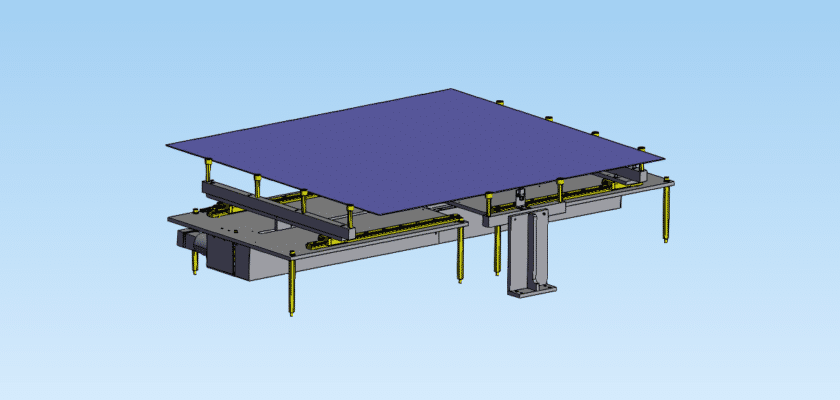

Achieving perfect alignment for thin materials is one of the most difficult challenges in automated manufacturing. This Thin Plate Positioning CAD desenho provides a sophisticated mechanical solution for securing and centering thin-gauge sheets, glass, or substrates. When dealing with thin plates, traditional high-pressure clamping can cause buckling or surface damage. This design solves those issues by utilizing a low-profile, distributed-force positioning system that ensures the workpiece is perfectly located against its datum points without compromising its structural flatness.

By downloading this technical desenho, you are gaining access to a masterclass in precision fixture design. The assembly features a combination of fixed stops and adjustable side-pressers that guide the plate into a repeatable “zero position” every time. This is essential for operations such as high-speed laser marking, automated optical inspection (AOI), or precision gluing where even a 0.1mm deviation can lead to a rejected part. The blueprint includes all necessary component details, from the hardened reference pins to the low-friction sliding blocks, making it an invaluable resource for anyone building a high-accuracy production cell.

Principais recursos:

- Three-Point Alignment Logic: Utilizes a classic 3-2-1 positioning principle modified for thin surfaces to ensure unambiguous part location with minimal contact.

- Low-Profile Edge Grippers: Designed to hold the plate by its extreme edges, leaving the top surface completely unobstructed for processing or scanning.

- Anti-Buckling Support: Features a flat, high-tolerance base plate that provides continuous support to prevent the material from sagging or vibrating during the operation.

- Micro-Adjustment Knobs: Includes fine-thread adjustment screws that allow the operator to calibrate the home position to within microns for ultra-precise tasks.

- Pneumatic or Manual Operation: The design is versatile enough to be driven by small-bore pneumatic cylinders for automation or manual toggle levers for batch prototyping.