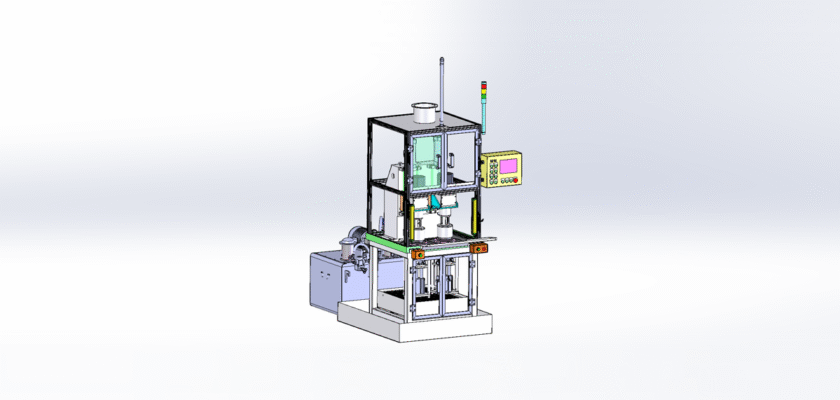

UM two-axis testing machine is a specialized piece of equipment designed to evaluate a product’s strength, durability, and performance by applying controlled forces or movements along two independent axes. This machine is crucial for quality control and R&D in a variety of industries, including automotive, aerospace, and electronics. By simulating real-world conditions, it can test a component’s fatigue life, stress tolerance, and deflection under dynamic loads. This comprehensive drawing, available for free download, provides a detailed blueprint of a professional-grade two-axis testing machine. It is an invaluable resource for mechanical engineers, quality assurance specialists, and students in materials science who want to understand the intricate mechanical and control systems that enable precise, repeatable testing. The plans illustrate the essential features, from the linear actuators and force sensors to the rigid frame, giving you the knowledge to design or simply gain a deeper understanding of this vital piece of lab equipment.

Principais recursos:

- Independent Axis Control: The drawing details the separate linear actuators on the X and Y axes, which can be programmed to apply forces independently or in combination to simulate complex loading scenarios.

- High-Precision Sensors: The blueprints showcase the integration of force and displacement sensors to provide accurate, real-time data on a product’s performance under load.

- Robust and Rigid Frame: The machine is engineered with a heavy-duty, stable frame to prevent unwanted vibrations and deflection, ensuring the test results are accurate and reliable.

- Automated Test Cycles: The design includes a control system that allows for the programming of repetitive test cycles, which is essential for conducting long-term fatigue and durability tests with consistency.