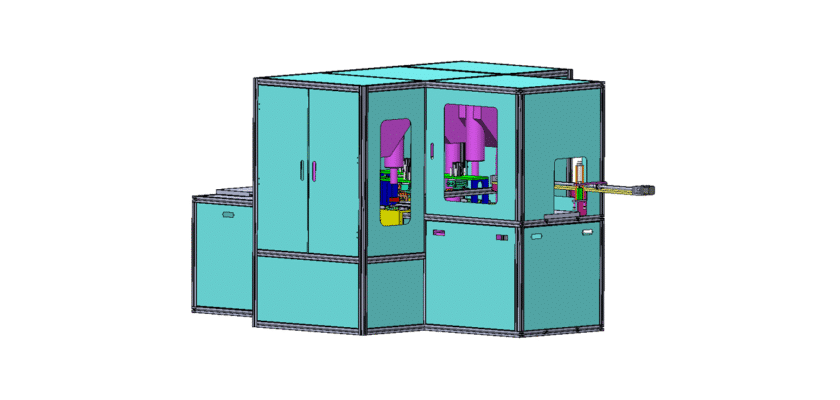

Enhance your understanding of advanced coating technology with our free technical drawing of an Automatic Ultrasonic Spraying Machine. This detailed drawing is a crucial resource for engineers, researchers, and students in fields such as electronics, medicine, and materials science. The document provides an in-depth look at the machine’s core components, including the ultrasonic nozzle, liquid pump system, and automated XYZ-axis motion control. By downloading this drawing, you can gain a clear understanding of how this precision equipment operates, which is essential for developing thin-film coatings, medical device coatings, and other micro-layer applications.

An ultrasonic spraying machine is celebrated for its ability to produce highly uniform, non-clogging sprays with minimal overspray, making it far more efficient and environmentally friendly than conventional pressure-nozzle systems. Our drawing highlights the intricate design that enables this precision, from the high-frequency vibration of the nozzle to the controlled liquid delivery system. This knowledge is invaluable for anyone involved in high-tech manufacturing, R&D, or academic study. Don’t miss this opportunity to add a critical piece of modern engineering documentation to your technical library.

Principais recursos:

- Ultrasonic Nozzle Technology: The drawing details the design of the nozzle that uses high-frequency sound waves to atomize liquid into a fine mist, ensuring a precise and uniform coating without droplet formation.

- Precision XYZ-Axis Control: The plans illustrate the automated robotic system that moves the nozzle with incredible accuracy, allowing for complex and consistent spray patterns on various surfaces.

- Liquid Delivery System: The document showcases the pump and fluid control system designed for continuous and stable liquid supply to the nozzle, which is crucial for maintaining coating thickness and consistency.

- Minimal Overspray & Waste: The design’s efficiency is highlighted, demonstrating how the technology significantly reduces material waste and overspray compared to traditional methods, making it ideal for costly materials.