Table of Contents

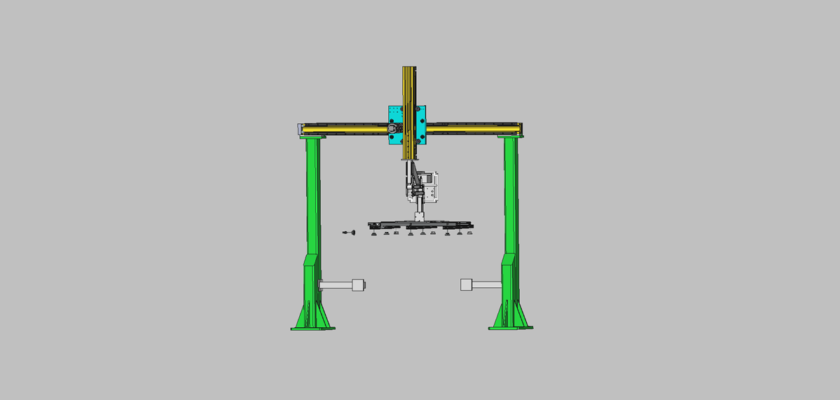

The Weighing Truss Manipulator is a sophisticated automated system designed to efficiently handle and accurately weigh materials in various industrial applications. This versatile manipulator integrates advanced weighing technology with a robust truss structure, ensuring precise measurements while facilitating the movement of heavy loads.

Key Features

- Integrated Weighing System: The manipulator is equipped with high-precision load cells that provide real-time weight measurements, allowing for accurate monitoring of materials during handling.

- Truss Structure: The lightweight yet strong truss design enhances stability and minimizes flex under load, ensuring reliable performance in demanding environments.

- Multi-Axis Movement: Capable of moving in multiple directions, the manipulator can efficiently position and weigh materials, improving workflow and productivity.

Components

- Base Frame: A sturdy foundation that supports the entire system, ensuring consistent performance and stability during operation.

- Truss Assembly: Made from high-strength materials, the truss framework offers durability while maintaining a lightweight profile for enhanced efficiency.

- Weighing Mechanism: Utilizes advanced load cells and electronic scales that provide accurate weight readings, integrated into the manipulator’s structure for seamless operation.

- Control System: Features an intuitive interface for monitoring weight data, allowing operators to make real-time adjustments and track material usage.

Performance Specifications

- Load Capacity: Designed to handle substantial weights, making it suitable for various industrial applications where accurate measurement is critical.

- Speed and Efficiency: Capable of rapidly weighing and moving materials, reducing processing times and enhancing overall operational efficiency.

- Durability: Built to withstand the rigors of industrial use, featuring components that resist wear and tear for long-term reliability.

Applications

- Manufacturing: Ideal for environments where precise material handling and weighing are essential, such as in production lines for pharmaceuticals, chemicals, or food processing.

- Logistics: Efficiently manages the weighing of goods in warehouses and distribution centers, streamlining inventory management and shipping processes.

- Quality Control: Can be utilized in quality assurance processes to ensure that materials meet specified weight criteria before further processing.

Safety and Maintenance

- Safety Features: Equipped with emergency stop functions and safety sensors to prevent accidents and ensure safe operation for personnel.

- Maintenance Accessibility: Designed for easy access to weighing components and critical systems, facilitating routine inspections and maintenance.

Conclusion

The Weighing Truss Manipulator is an advanced solution for modern industrial needs, combining precise weighing capabilities with robust design and efficiency. Its integration of automation and accurate measurement makes it an invaluable tool for enhancing productivity and safety in various operational settings.