Streamline your electrical and electronics projects with our free, detailed drawing of a Máquina de etiquetagem de fios. In industries from telecommunications to aerospace, proper wire identification is essential for safety, maintenance, and troubleshooting. A wire labeling machine automates the tedious task of printing and applying markers to cables and wires, ensuring every connection is clearly and accurately identified. This not only dramatically increases production speed but also eliminates human error, guaranteeing system integrity and simplifying future repairs.

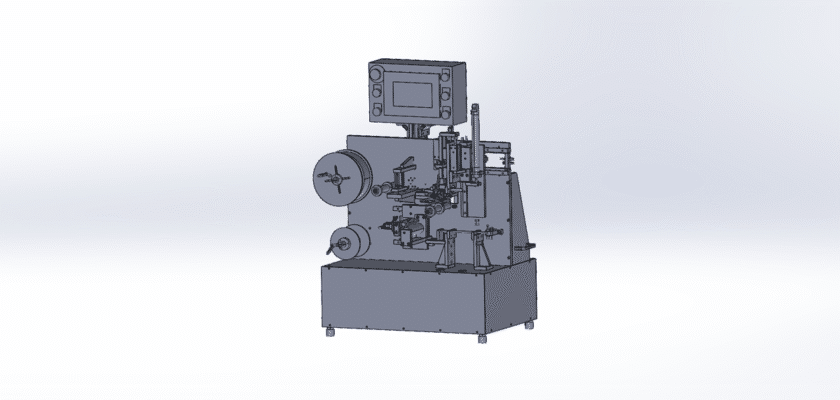

This comprehensive CAD drawing is a must-have resource for engineering students, technicians, and professionals involved in electrical design and manufacturing. The drawing provides an in-depth look at the mechanical, electrical, and control systems that make this machine so effective. It illustrates the intricate feed mechanism that handles various wire gauges, the precision printer that applies clear text or codes, and the cutting and application systems that complete the process. By studying this drawing, you’ll gain a deeper understanding of the automation principles behind a crucial piece of equipment that brings clarity and order to complex wiring systems.

Principais recursos:

- Automated High-Speed Labeling: The machine is designed to automatically feed, print, and apply labels to wires at a rapid pace, significantly increasing efficiency in production environments and saving valuable time.

- Versatile Wire Compatibility: The drawing highlights the adjustable feeding and clamping mechanisms, which allow the machine to accommodate a wide range of wire diameters and insulation types, making it suitable for diverse applications.

- Precisão e exatidão: The design showcases the integration of precise sensors and a high-resolution printing head, ensuring that each label is perfectly aligned, legible, and correctly positioned on the wire every time.

- Fluxo de trabalho simplificado: The machine’s automated process eliminates the need for manual wire marking, reducing the risk of errors and providing a consistent, professional finish that is easy to read and maintain for the life of the product.