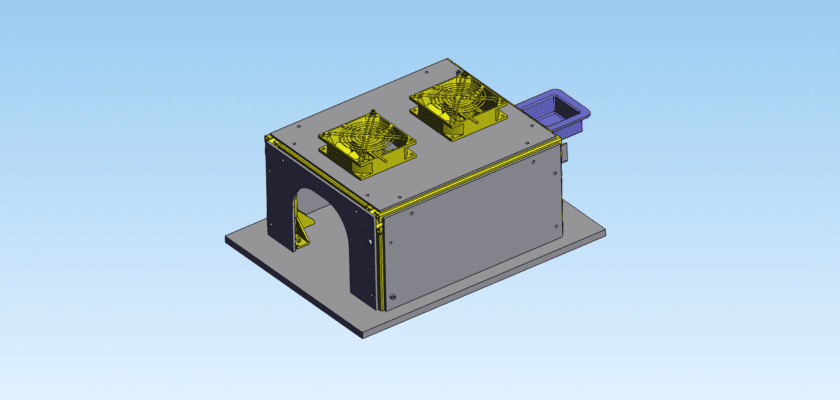

Optimize your production cycle times with our Workpiece Cooling on Conveyor Belts technical drawing. In high-speed manufacturing, parts often exit presses or ovens at temperatures too high for immediate packaging or secondary operations. This CAD desenho provides a detailed blueprint for an integrated cooling tunnel and blower assembly designed to accelerate heat dissipation while parts are in transit. By implementing a structured cooling zone, you can prevent thermal deformation and reduce the “buffer” space required between workstations.

This download provides a comprehensive look at the airflow paths required for uniform cooling. The layout includes specifications for high-velocity axial fans, adjustable ducting, and perforated belt selections that allow for 360-degree air circulation around the workpiece. By studying this desenho, engineers can analyze the placement of baffles and air knives designed to break the thermal boundary layer on the part surface. At MechStream, we prioritize practical, energy-efficient solutions for industrial thermal challenges. Download this cooling system layout today to improve your throughput and ensure part quality remains consistent from start to finish.

Principais recursos:

- High-Efficiency Airflow Geometry: Features optimized plenum chambers and nozzles to ensure air is directed precisely at the workpieces.

- Variable Speed Fan Integration: Detailed mounting and wiring specs for VFD-controlled fans to adjust cooling intensity based on material thickness.

- Perforated Mesh Belt Selection: Includes specifications for heat-resistant wire mesh or perforated plastic belts to maximize bottom-side cooling.

- Integrated Heat Shielding: Features insulated side panels in the drawing to protect nearby operators and sensitive electronic components from radiant heat.

- Modular Tunnel Sections: Designed in segments, allowing the cooling zone to be extended or shortened based on your specific cycle time requirements.