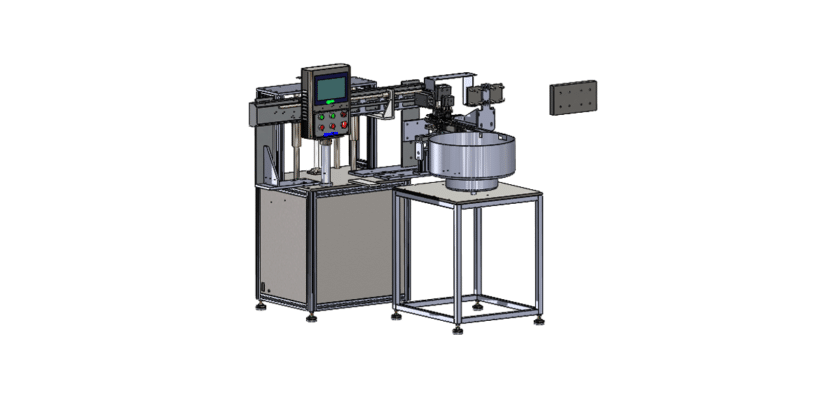

The Robot Screw Implantation Machine is an advanced automated solution designed for high-precision screw installation in a wide range of industrial applications. Featuring robotic arms, this machine combines speed, accuracy, and flexibility to implant screws into components with minimal human intervention. Ideal for mass production environments, it offers a consistent and reliable solution for screw implantation, ensuring optimal fastening with precise torque control while enhancing overall production efficiency.

Key Features:

- Robotic Precision: Equipped with a robotic arm, the machine offers precise, repeatable screw implantation, ensuring that screws are securely fastened into components with consistent torque every time.

- Automated Operation: Fully automated, it eliminates manual handling, reducing labor costs, increasing efficiency, and minimizing human error in the screw implantation process.

- Advanced Torque Control: The machine is equipped with sophisticated torque control technology, allowing screws to be implanted to the exact required specifications, ensuring secure and reliable fastening.

- High-Speed Performance: Capable of rapid screw implantation, the machine significantly enhances production throughput while reducing cycle times, making it ideal for high-volume manufacturing environments.

- Flexible and Adaptable: Suitable for a wide range of screw sizes, types, and component designs, this system can be easily adjusted to accommodate various applications across different industries.

- User-Friendly Interface: The intuitive control panel allows for easy programming, operation, and monitoring of the robot’s movements and screw implantation process, minimizing setup time and optimizing workflow.

- Durable and Reliable: Built with high-quality materials and designed for continuous operation, the machine offers long-term durability and minimal maintenance, even in high-demand production environments.

Applications:

- Perfect for industries such as automotive manufacturing, electronics assembly, and appliance production, where consistent and high-precision screw implantation is critical.

- Suitable for a variety of products requiring automated screw fastening, including motor assemblies, machinery, enclosures, and more.

The Robot Screw Implantation Machine is a high-performance solution for automating the screw fastening process, combining cutting-edge robotic technology with high-speed and precision to improve production efficiency, product quality, and overall manufacturing reliability.