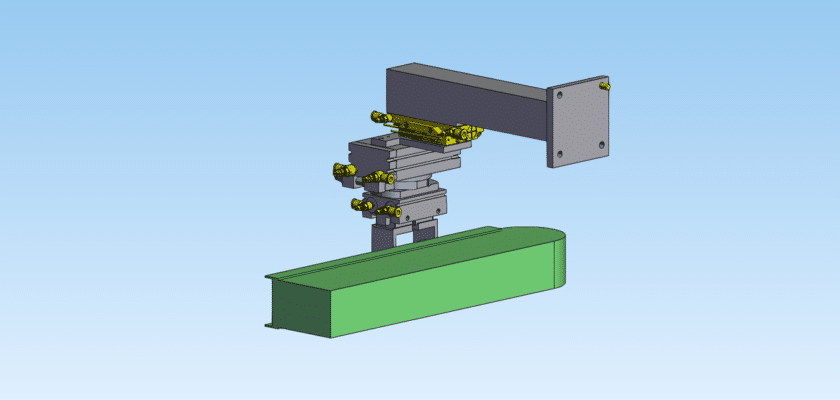

The Rotation and Clamping Assembly is a vital sub-system in modern automation, providing the dual functionality of secure workpiece retention and controlled angular positioning. This professional engineering drawing offers a deep dive into a high-performance mechanism designed to withstand the rigors of repetitive industrial cycles. Whether utilized in CNC machining, robotic welding, or automated assembly lines, a well-engineered rotation and clamping unit ensures that parts remain perfectly stationary during processing while allowing for seamless transition between different working angles.

Our technical drawing provides comprehensive views of the internal bearing structures, pneumatic or manual clamping linkages, and the rotational drive interface. By downloading this blueprint, you eliminate the guesswork involved in designing complex multi-axis fixtures. The assembly is engineered to minimize “play” or backlash, ensuring that once the clamp is engaged and the rotation is locked, the workpiece remains within strict positional tolerances. This documentation serves as an excellent starting point for engineers looking to customize their own modular work-holding solutions or for students seeking to understand the integration of rotary motion with mechanical locking systems.

Streamline your design phase and reduce prototyping errors by utilizing this industry-standard reference. MechStream continues to support the global engineering community by offering these high-quality, downloadable assets at no cost.

Key Features:

- High-Torque Stability: Engineered to maintain a firm grip even under significant lateral forces during machining or high-speed rotation.

- Precision Bearing Integration: Detailed layout for low-friction rotation, ensuring smooth movement and long-term durability.

- Modular Interface Design: Features a versatile mounting pattern that allows the assembly to be integrated into various machine beds or robotic arms.

- Compact Footprint: Optimized spatial arrangement of components to provide maximum clamping force within a minimal operational envelope.

- Clear Tolerance Specifications: Includes precise machining limits for all mating parts to guarantee a perfect fit-and-finish during manufacturing.