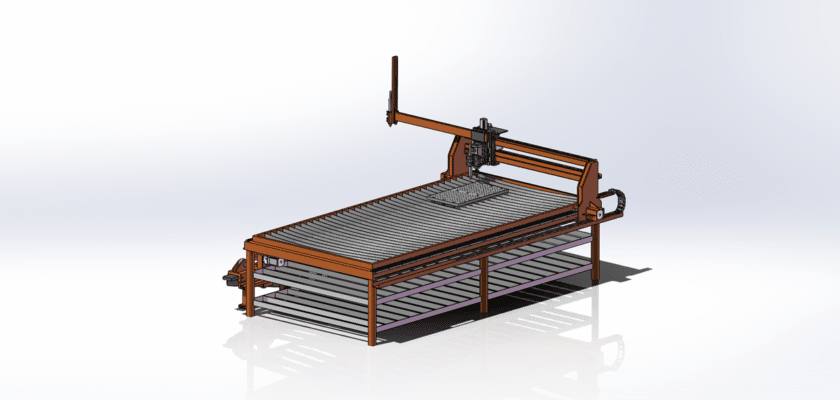

Четырехкоординатный плазменный резак Patton с ЧПУ — это современный инструмент, предназначенный для высокоточной резки в различных промышленных условиях. Благодаря усовершенствованной четырехкоординатной конструкции этот станок обеспечивает большую универсальность и точность резки по сравнению с традиционными двух- или трехкоординатными плазменными резак. Он идеально подходит для резки сложных форм и замысловатых конструкций из таких материалов, как сталь, алюминий и другие металлы.

Возможность четырёхкоординатной обработки обеспечивает повышенную гибкость, позволяя пользователям выполнять резку под разными углами, обеспечивая более детальную и точную резку. Система ЧПУ обеспечивает автоматическую резку, снижая влияние человеческого фактора и повышая производительность. Операторы могут легко программировать траекторию, скорость и мощность резки через удобный интерфейс, что делает систему эффективной как для крупносерийного производства, так и для небольших индивидуальных проектов.

Четырехкоординатный станок плазменной резки Patton с ЧПУ, оснащенный мощным плазменным резаком, обеспечивает высокую скорость резки и минимальные зоны термического воздействия, что обеспечивает более чистый рез и снижает необходимость вторичной обработки. Прочная конструкция станка и передовые технологии гарантируют его долговечность и надежность даже в сложных условиях эксплуатации.

Четырехкоординатный плазменный резак Patton с ЧПУ обеспечивает исключительную производительность, обеспечивая высокое качество каждого реза, будь то создание прототипов, серийное производство или изготовление сложных конструкций. Низкие требования к техническому обслуживанию и высокая эффективность работы делают его экономичным решением для компаний, стремящихся оптимизировать процессы резки.