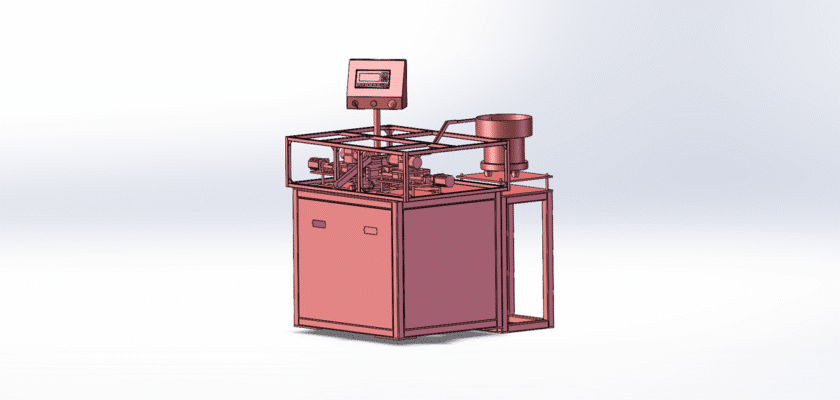

Explore the precision and speed of modern manufacturing with our free technical drawing of a High-Speed Automatic Headphone Punching Machine. This is an indispensable resource for mechanical engineers, industrial designers, and students interested in consumer electronics production. The comprehensive drawing provides a detailed view of all key components, including the punching die, pneumatic press, automated feeding mechanism, and control system. By downloading these plans, you will gain a deep understanding of how this machine is designed to efficiently and accurately create intricate shapes in headphone components, which is critical for mass production.

A headphone punching machine is a highly specialized piece of equipment that balances high-speed operation with incredible precision to avoid damaging delicate materials. Our drawing set offers a clear representation of how the feeding mechanism positions the material precisely before the punching die strikes, ensuring a clean and consistent cut. This knowledge is invaluable for system design, troubleshooting, and educational projects. Whether you are building a new prototype, studying automated manufacturing, or simply curious about how consumer electronics are made, this drawing is an essential addition to your professional and educational library.

Ключевые особенности:

- High-Speed Punching: The drawing details the design of the pneumatic or hydraulic press that delivers a rapid and powerful force, enabling a high volume of parts to be produced per minute.

- Automated Feeding System: The plans illustrate the intricate feeding mechanism that accurately positions the material under the punching die, ensuring repeatable and precise cuts.

- Precision Die and Punch: The document showcases the design of the custom-made die and punch set, which is critical for creating complex and accurate shapes without deforming the material.

- Integrated Control: The design highlights a simplified control unit that synchronizes the feeding and punching actions, ensuring the entire process is automated and efficient.