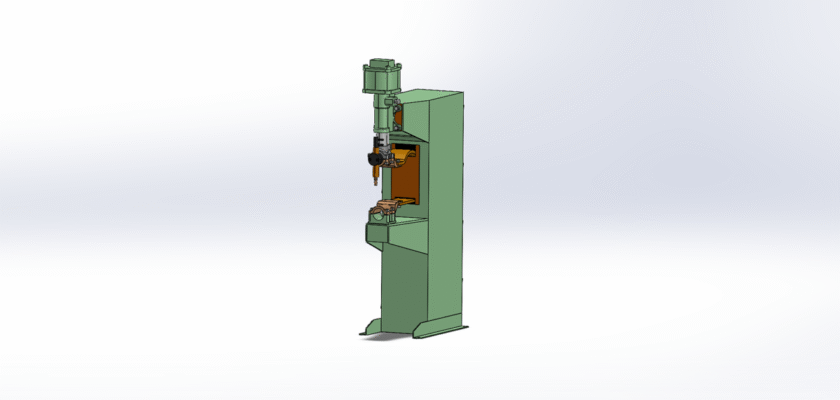

Unlock the potential of modern metal fabrication with our detailed drawing of a Spot Welding Machine. This free, downloadable resource is an indispensable tool for engineers, welders, and students eager to understand the principles of resistance welding. The drawing provides a comprehensive view of a machine designed to join sheet metal by applying pressure and passing a high-current electrical charge through two electrodes. This process melts the metal at a specific “spot,” creating a strong, permanent bond without the need for filler material. Our diagram illustrates the machine’s critical components, including the transformer that converts voltage to high amperage, the electrodes that clamp the workpieces, and the control system that regulates time and current. This resource is perfect for academic projects, professional design references, or simply to deepen your knowledge of this fundamental industrial process. The design is optimized for speed and repeatability, making it a cornerstone of manufacturing in industries from automotive to electronics.

Ключевые особенности:

- Efficient Resistance Welding: The machine uses the natural electrical resistance of the metal to generate localized heat, ensuring a fast and clean weld with minimal heat affected zone.

- Integrated Pressure System: The electrodes apply precise clamping force to the workpieces, ensuring optimal contact and the formation of a solid weld nugget as the molten metal fuses.

- Transformer Power: The core of the machine is a high-power transformer that steps down voltage and steps up current, delivering the massive energy required to melt metal in milliseconds.

- Control and Automation: The design incorporates a control unit for programming weld time, current, and pressure, allowing for consistent, high-quality welds and making it suitable for automated production lines.

- Durable Copper Electrodes: The electrodes are made from copper alloy to ensure excellent electrical and thermal conductivity, concentrating the heat where it’s needed most while remaining durable under high-pressure, high-temperature conditions.