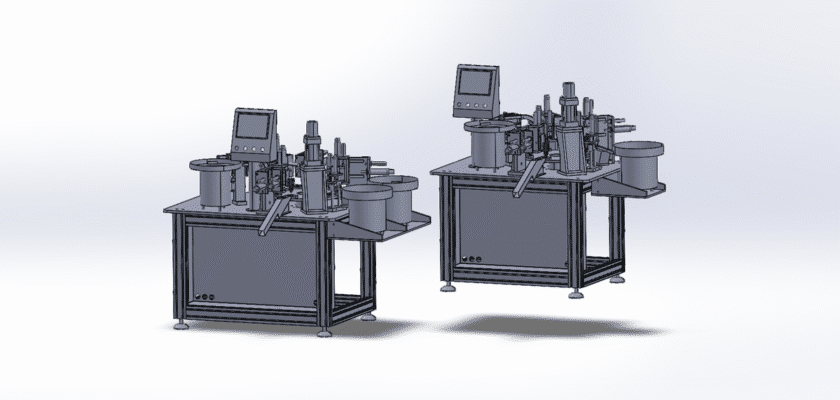

Revolutionize your manufacturing process with our free, high-quality CAD drawing of an Automatic Hardware Loading and Assembly Machine. This invaluable resource is perfect for engineers, students, and manufacturers seeking to understand the intricate design and functionality of automated assembly lines. Automatic hardware assembly machines are the backbone of modern mass production, crucial for industries ranging from electronics and automotive to consumer goods and medical devices. They are designed to handle repetitive, high-precision tasks with unparalleled speed and accuracy, drastically reducing labor costs and human error.

This detailed drawing provides a comprehensive look at the machine’s complex subsystems, including the feeding mechanisms, robotic manipulators, and integrated control systems. By studying this drawing, you can gain deep insights into how automated systems are engineered to perform a variety of tasks, from sorting and orienting components to fastening, welding, and quality inspection. This design highlights the principles of fixed and programmable automation, showcasing how a well-designed machine can be both highly efficient for a single task and flexible enough for various product configurations.

Ключевые особенности:

- High-Speed Component Feeding: The design illustrates advanced vibratory bowl feeders and pick-and-place robots that ensure a continuous and precise supply of hardware components to the assembly stations, minimizing downtime and maximizing throughput.

- Комплексный контроль качества: The machine incorporates vision systems and sensors for real-time inspection, automatically detecting and rejecting defective parts to maintain a high level of product quality without manual intervention.

- Modular and Flexible Design: The drawing shows a modular architecture that allows for easy reconfiguration and scalability, enabling the machine to be adapted for different product lines or assembly tasks with minimal retooling.

- Расширенная система управления: The system is governed by a sophisticated Programmable Logic Controller (PLC) that coordinates all mechanical and robotic movements with high precision, ensuring reliable and repeatable assembly operations.