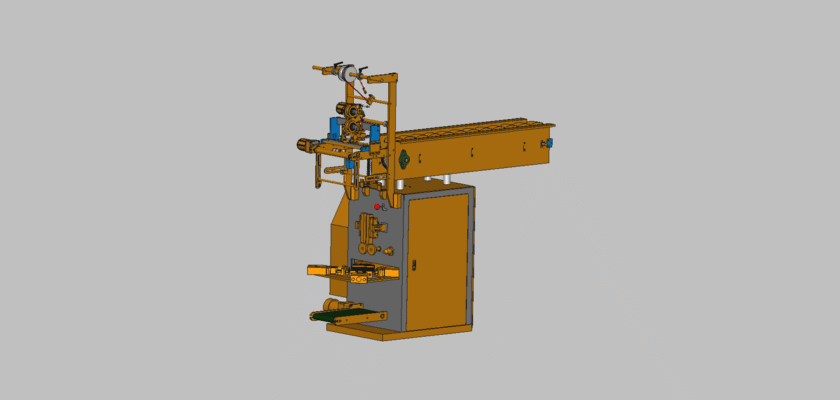

Are you looking to optimize your packaging process or simply study the design of a highly efficient machine? Download our free, detailed drawing of a Vertical Form Fill Seal machine today. VFFS machines are at the heart of modern packaging, providing a fast, automated solution for bagging everything from snacks and powders to liquids and granules. Their vertical design not only saves floor space but also leverages gravity for precise and rapid filling, making them an indispensable tool in a wide range of industries including food and beverage, pharmaceuticals, and chemicals.

This comprehensive drawing package provides an in-depth look at the VFFS machine’s components and assembly. It is perfect for mechanical engineering students, designers, and professionals seeking to understand the mechanics behind this powerful piece of equipment. The provided drawings are suitable for various CAD software, allowing you to examine the intricate details and operational principles. By studying this drawing, you can gain valuable insights into the design considerations for high-speed automation, material handling, and sealing technology. Don’t miss this opportunity to access a valuable resource that can boost your knowledge and next project.

Ключевые особенности:

- Compact Vertical Design: The VFFS machine’s upright structure minimizes its footprint, making it ideal for facilities with limited space. This design also utilizes gravity to assist with product filling, increasing speed and efficiency.

- Универсальное применение: The machine can be adapted to handle a wide variety of products, including free-flowing solids, powders, granules, and even liquids, by integrating different filling systems such as multi-head weighers, auger fillers, or volumetric cups.

- Automated and High-Speed Operation: From unwinding the film to forming, filling, and sealing the final bag, the entire process is automated. Modern VFFS machines are capable of high-speed production, significantly increasing output and reducing labor costs.

- Multiple Bag Styles: The machine can produce various bag formats from a single roll of film, including pillow bags, gusseted bags, and block bottom bags, offering flexibility to meet diverse product and market needs.