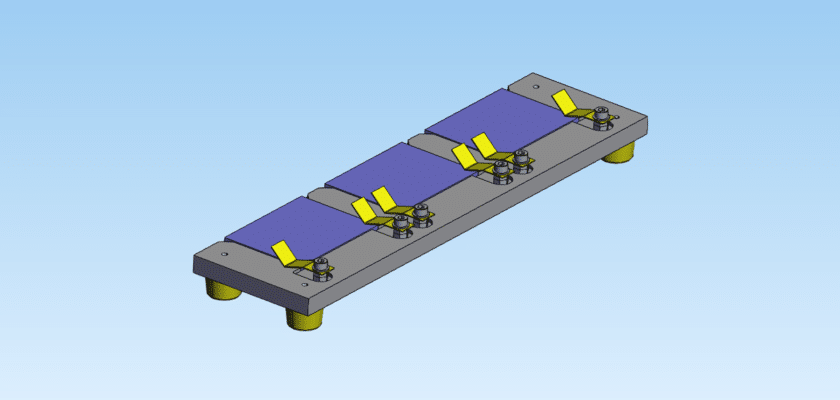

Consistency is the backbone of high-quality fabrication, and this Professional Welding Fixture drawing provides the essential blueprints for maintaining perfect alignment throughout the thermal cycle. A well-engineered fixture does more than just hold parts; it acts as a heat sink, controls thermal distortion, and ensures that every assembly is identical to the last. This technical document details a heavy-duty, modular welding jig designed to withstand the harsh environment of the welding cell while providing unobstructed access for either a manual welder’s torch or a robotic arm.

The documentation covers the integration of toggle clamps, precision locating pins, and heat-resistant standoffs. By downloading this drawing, you gain access to a design that prioritizes rapid loading and unloading—minimizing non-productive time and maximizing throughput. The layout includes specific tolerances for “gap management,” ensuring that joints are positioned perfectly for optimal penetration and strength. Whether you are building a fixture for a complex tubular chassis, a sheet metal enclosure, or a heavy structural bracket, this resource provides the verified mechanical data and material callouts (such as copper-plated hardware to resist spatter) required for a professional-grade build.

Don’t let part movement or warping compromise your weld integrity. Utilize this industry-standard reference to build a dedicated welding station that enhances accuracy and safety. At MechStream, we provide the blueprints that bridge the gap between loose parts and precision-welded assemblies. Download this high-quality technical asset today.

Ключевые особенности:

- Thermal Distortion Control: Engineered with strategic clamping points and heat-dissipating base materials to keep the workpiece within dimensional specs during cooling.

- Ergonomic Access Windows: Designed with “line-of-sight” clearances to allow for easy torch manipulation and optimal welding angles in tight corners.

- Spatter-Resistant Components: Includes specifications for shielded threads and copper-coated clamps to prevent weld berries from seizing moving parts.

- Modular Locating System: Features a grid of dowel holes and T-slots for quick reconfiguration, allowing the fixture to adapt to multiple part variations.

- Repeatable Zero-Point Datums: Detailed schematics for hardened locating pins that ensure every part is loaded in the exact same spatial coordinate every time.