Ensure every cylindrical component meets your exact tolerances with our professional Outer Diameter Measuring Gauge drawing. In precision manufacturing, verifying the outside diameter is often the most frequent inspection task. This technical CAD resource provides a comprehensive blueprint for various gauging architectures, including Bench-top Comparator Stands, C-Frame Snap Gauges, и V-Block Metrology Fixtures. By downloading this file from MechStream, you gain access to a design that eliminates “operator feel” and provides objective, high-resolution measurement data.

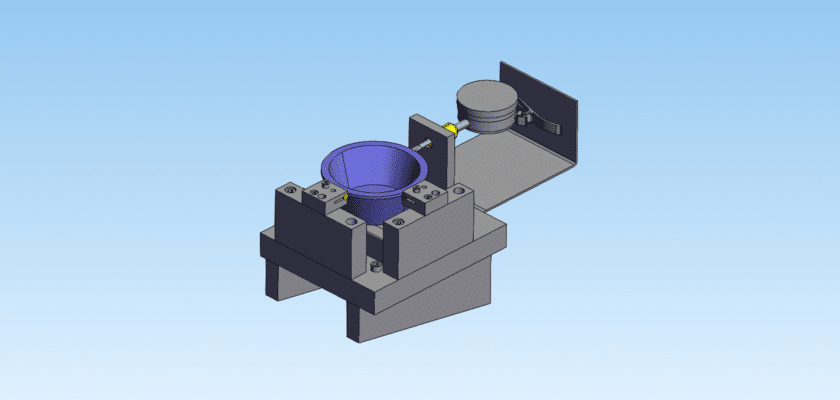

The design featured in this package focuses on the Comparative Measurement architecture. The drawing includes detailed layouts for a stable, heavy-duty base and a precision-adjustable measuring arm. A major challenge in OD measurement is maintaining parallelism between the measuring anvils; by utilizing this blueprint, you can implement a design featuring self-aligning contact points and a “fine-feed” adjustment screw for zeroing the gauge against a master ring or block. This is an essential asset for designers of automotive piston inspection lines, medical tubing quality checks, and aerospace shaft manufacturing.

Our technical documentation prioritizes thermal stability and wear resistance. The assembly is designed with Carbide-Tipped Anvils to prevent measurement drift caused by surface wear over thousands of cycles. Whether you are building a manual inspection station or an automated “Pass/Fail” sorting gate, this drawing provides the exact geometric tolerances, spring-force specifications for the probe, and material callouts required for a professional-grade metrology installation.

Ключевые особенности:

- High-Resolution Probe Integration: Specifically engineered for LVDT (Linear Variable Differential Transformer) or digital drop indicators with 0.001mm resolution.

- Precision V-Block or Center Support: Detailed blueprints for holding the workpiece perfectly perpendicular to the measuring axis.

- Adjustable Measuring Pressure: Features a spring-loaded mechanism to ensure constant contact force, preventing deformation of thin-walled or “soft” workpieces.

- Thermal Expansion Compensation: Uses low-expansion materials (such as Invar or high-grade cast iron) to ensure accuracy in non-climate-controlled factory environments.

- Modular Anvil Heads: Includes designs for flat, spherical, or blade-style anvils to measure different geometries like splines or grooves.