Table of Contents

Key Features

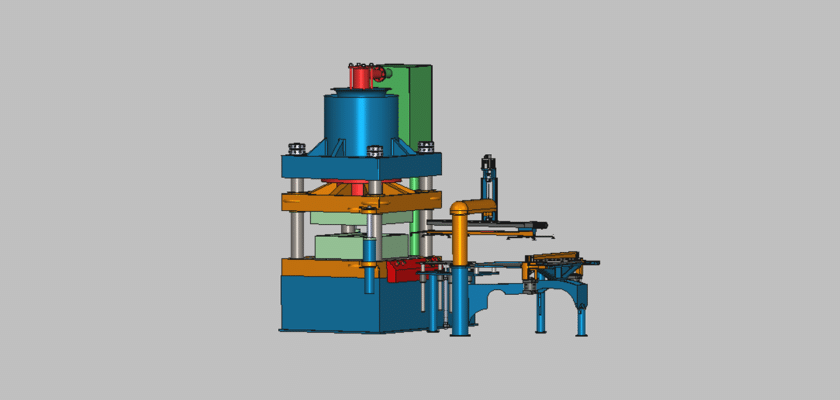

The Pressing Machine with Truss Robot Automatic Loading is an innovative automated system designed to enhance production efficiency in manufacturing environments. This integrated solution combines a high-performance pressing machine with an advanced truss robot for seamless loading and unloading operations, optimizing workflow and reducing manual labor.

- Automatic Loading System: The truss robot is equipped with an intelligent loading mechanism that automatically positions materials into the pressing machine, minimizing downtime and maximizing throughput.

- Robust Truss Structure: The truss design provides exceptional stability and strength, ensuring reliable operation even under heavy loads.

- Precision Control: The system employs advanced sensors and control algorithms to ensure accurate placement and alignment of materials during the loading process.

Components

- Pressing Machine: A high-capacity machine designed for various pressing applications, featuring adjustable settings for different material types and thicknesses.

- Truss Robot: Composed of a lightweight yet durable truss framework, the robot features multiple axes of movement for flexible and precise handling.

- Gripping Mechanism: Incorporates specialized grippers that can adapt to various shapes and sizes of materials, ensuring secure handling during operations.

- Control System: An intuitive interface that allows operators to monitor and control the entire automated process, with real-time feedback and diagnostics.

Performance Specifications

- Load Capacity: Designed to handle heavy materials efficiently, making it suitable for high-demand production environments.

- Speed and Efficiency: Capable of rapid loading and unloading cycles, reducing overall processing time and improving productivity.

- Durability: Constructed from high-strength materials, the system is built to withstand the rigors of continuous operation in industrial settings.

Applications

- Manufacturing: Ideal for operations that require consistent and reliable pressing of materials, such as metal forming, plastic molding, or composite pressing.

- Automotive Industry: Suitable for use in automotive manufacturing, where precision and speed are critical for component production.

- Aerospace and Defense: Can be utilized in the production of aerospace components, where high tolerances and reliability are essential.

Safety and Maintenance

- Safety Features: Equipped with emergency stop buttons, safety sensors, and protective enclosures to ensure safe operation for personnel.

- Maintenance Accessibility: Designed for easy access to critical components, facilitating routine inspections and maintenance to ensure long-term reliability.

Conclusion

The Pressing Machine with Truss Robot Automatic Loading represents a significant advancement in manufacturing automation. Its combination of robust design, precision engineering, and automated loading capabilities makes it an invaluable asset for enhancing efficiency, productivity, and safety in various industrial applications.