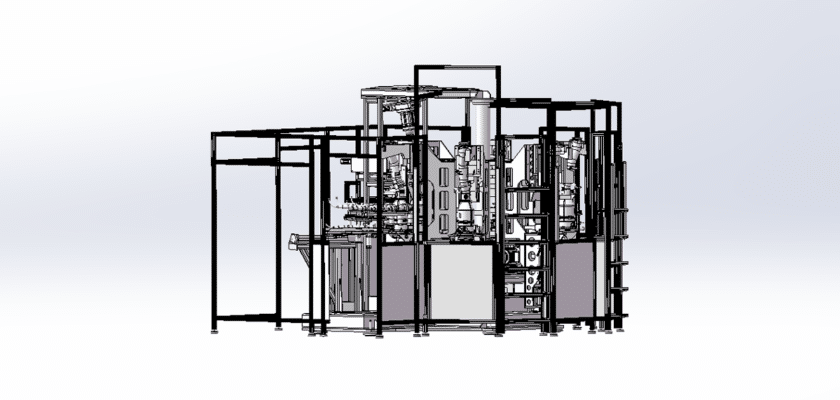

This detailed drawing of the Multi-Station Combination Non-Standard Automated Machinery illustrates a versatile system designed for specialized manufacturing processes that require tailored solutions. Ideal for industries such as automotive, aerospace, and custom fabrication, this machine enhances efficiency while accommodating unique production needs.

Key Features of the Drawing:

- Multi-Station Configuration: The machine features multiple workstations, allowing for simultaneous processing of various operations, such as assembly, welding, and inspection, which optimizes workflow and increases throughput.

- Customizable Automation: Designed for non-standard applications, the system can be easily configured to meet specific manufacturing requirements, making it adaptable for diverse projects.

- Integrated Control Systems: Advanced control technology enables precise monitoring and adjustment of parameters, ensuring consistent quality and performance across different tasks.

- High Precision Component Handling: Equipped with precision tools and fixtures, the machine ensures accurate placement and processing of components, reducing the risk of defects.

- Удобный интерфейс: An intuitive control panel allows operators to easily program and manage multiple tasks, facilitating quick adjustments for various production scenarios.

- Robust and Durable Design: Constructed from high-quality materials, the machinery is engineered for longevity and reliability, ensuring optimal performance in demanding production environments.

- Versatile Application Compatibility: Capable of handling a wide range of materials and processes, this machine is suitable for custom solutions across multiple sectors.

This drawing serves as an essential reference for engineers and manufacturers seeking to implement effective and efficient automated solutions for non-standard applications in their production lines.