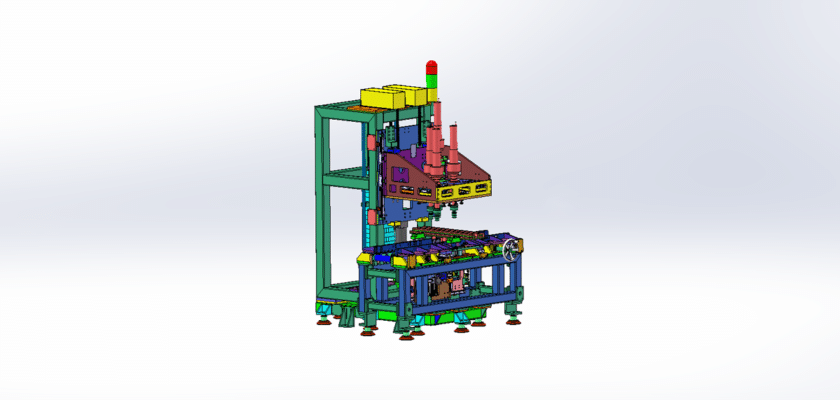

This detailed drawing of the Riveting Machine illustrates a specialized system designed for the automated riveting of components in various manufacturing applications. Ideal for industries such as automotive, aerospace, and construction, this machine enhances assembly efficiency while ensuring high-quality, durable connections.

Key Features of the Drawing:

- Automated Riveting Process: The machine employs advanced technology to perform precise riveting operations, significantly increasing throughput and reducing manual labor costs.

- High Precision Alignment: Equipped with alignment fixtures and guides, the system ensures accurate positioning of components during the riveting process, minimizing the risk of misalignment and defects.

- User-Friendly Control Interface: An intuitive control panel allows operators to easily set parameters, monitor the riveting process, and make quick adjustments for different materials and rivet sizes.

- Robust Construction: Built from high-quality materials, the machine is designed for durability and reliability, providing consistent performance in high-volume production environments.

- Integrated Safety Features: Safety mechanisms, including emergency stop buttons and protective covers, ensure safe operation and minimize risks during use.

- Versatile Application Compatibility: Capable of riveting a wide range of materials, including metals and plastics, the machine is adaptable for diverse applications across multiple sectors.

- Efficient Material Handling: The design may include automated feeding systems to streamline the workflow, enhancing overall operational efficiency and reducing cycle times.

This drawing serves as a vital reference for engineers and manufacturers seeking effective and efficient solutions for riveting operations in their production lines.